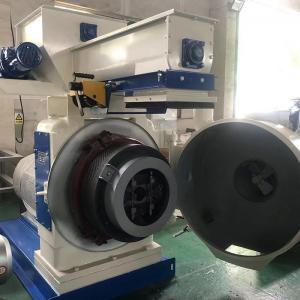

20TPH 5mm Vertical Pellet Mill 508 Small Wood Pellet Maker

Add to Cart

Vertical Wood Pellet Mill Wood Pellet Manufacturing Equipment 508

Pelletizing is the process of compressing or molding a material into the shape of a pellet. A wide range of different materials are pelletized including chemicals, iron ore, animal compound feed, plastics, waste materials, and more. Wood pellet mill is designed to processing wood or biomass or animal feed to the pellet manfacturing equipment .

The Raw Material From Wood Log, Wood Sawdust, Grass , Alfalfa , Hemp, Rice Husk , Straw , Organic Fertilizer , Cow Dung, Waste Paper , Organic Waste and Other Raw Material.

The request for the raw material :

Raw material :

Require size: 3--5mm;

Moisture content: 10-15%

Capacity can be customzied from 1-20t/h !

How to make the pellets ,generally it is processed by below several equipment :

The main euqipment :

| Pellet Mill Machine | |||

| Model :420,508 ,650 | |||

| Model 420 | |||

| Capacity :1-1.5t/h | |||

| Power :90kw | |||

| Weight :3200kg | |||

| Dimension :2500*1100*1600mm | |||

| Model :508 | |||

| Capacity :1.5-2t/h | |||

| Power :132kw | |||

| Weight 5300 | |||

| Dimension :2800*1500*2500mm | |||

| Model :650 | |||

| Capacity :2.5-3t/h | |||

| Power :200kw | |||

| Ring die :Customized alloy steel or 4Cr13 | Weight 9000kg | ||

| Dimension 3530*1580*2400mm | |||

Note :

1. Even if the same raw material is processed by the same type of

Pellets mill , the output will be different due to the state of the

raw material, moisture content and other conditions. Please contact

us and tell us the status of your raw materials and we will provide

more information.

2. Not only 6~10mm, we can customize the final pellet size for you.

3. We can customize each part of the grass Pellets Press for you

such as color, motor brand, voltage, size, function, etc

Final different wood Pellet

Diameter of final pellets: 6mm,8mm,10mm,12mm.

Length of wood pellet: Ajustable wood pellets

Applicate: Home fireplace, power plant etc.

5mm vertical pellet mill

508 small wood pellet maker

Generally pellete line processing :

1.This machine chip the raw material into small chips, these chips are raw material of chipboard, density beaverboard and wood fiber board, also could be burning material as sort of fuel.

2. Grinding processing :The hammer mill system can make wood chips into wood sawdust . The hammer mill is applied mainly to grinding the raw material to make it suiable to make pellets.

3. Drying :To dry materials and remove the moisture from 50 % to 15-17 % . The best moisture content to pelletizing is 13-15%, so our rotary dryer is designed to reduce the moisture of the unqualified raw material, for which the moisture is too high.

4. Pelletizing process:It is suitable for the production of biomass pellets of various biomass raw materials. Using SIEMENS motor, high-precision gear transmission, SKF bearings, and is equipped with a forced feeding device to ensure the smooth operation of the machine. Core component ring die, using 42CrMo.

5. The cooling system can immediately cool the biomass pellets to room temperature. When the pellets come out of the pelletizer, the temperature will be around 70°C, and then through the instant cooling effect of the cooler, the hardness of the pellets will become stronger. So as to obtain better hardness and strength

6. The packing processing :The qualified pellet is packed in the bag from 10-100kg .The sewing machine is used to close the bag which makes pellet dry and water proof .

FAQ:

How did you define your pellet mill model as 420 / 508, etc. ?

The model is defined based on the diameter of the ring die mould.

For example, mould 420 means that the diameter of the ring die is 420 mm.

2) what kind of raw material that the ring die mould is made of?

There are two kinds of ring die mould in the market. one is made of alloy steel, the other is made of stainless steel. the former is cheaper than the latter.

We adopt stainless steel ring die and press roller sheel in our machine.

3) what about the size of the final product wood pellet?

the size is adjustable accroding to your requirement.

the diameter range of the sawdust pellet is ø6-10 mm by using different size of ring die mould.

the length of the pellet could be adjusted by the cutter on the machine.

5) What is the suitable moisture (water content) of the raw material that easy to make pellet?

the ideal moisture range is from 15% to 18% .

6) will you dispatch engineer to install the wood pellet mill machine (production line)?

Yes. we will dispatch engineer to do the service just based on the requirement of customers.

9) where is your factory located? how could I get there?

Our factory is located in Liyang ,about 80km to Nanjing airport .