Add to Cart

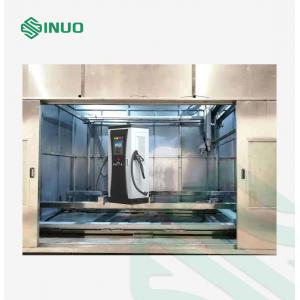

IPX9 High Temperature And Pressure Water Jet Test System SN4412C-F

Complied Standards & Clauses for EV Charging Pile IPX9 High Temperature And Pressure Water Jet Test

System

The IPX9 Open Rain Room SN4412C-F conforms to the standard

requirements of IEC 60068: 2022, IEC60529:2020 etc.

Technical Parameter for EV Charging Pile IPX9 High Temperature And Pressure Water Jet Test

System

| The main technical parameters | |

| Inner Frame Dimension | Depth 2000× width 2500× height 4000mm |

| Outer Frame Dimension | Approx. Depth 2500× Width 45,000 × height 4500mm (glass house, drainage tank and ground engineering users handle by user). |

| User Maximum Sample | Depth 1500× width 1000× height 500mm, sample weight: 650KG. |

| Spray System | It is composed of an Italian high pressure and high temperature water pump, high pressure and high temperature water pressure meter, high pressure and high temperature solenoid valve and high pressure and high temperature hydraulic pipe. |

| Jet Water Temperature | RT ~ 80℃ can be set (RT is the ambient temperature) |

| Injection Angle | The spray can cover the entire surface of the sample, and the spray Angle is perpendicular to the sample surface. |

| Jet Pressure | 8000~10000Kpa |

| Spray Flow | 14~16L/min |

| Distance from Nozzle to Sample | 175±25mm |

| Spray time | 30S/m2 (configurable) |

| Run Time Control | 1s ~ 9999h59min59s(adjustable) |

| Receiver Surface | Top and sides of the product |

| Water Jet Pressure gauge | Water spray pressure can be displayed |

| Control System | The company independently developed touch screen control system |

| Heating Tank (incubator) | one |

| Sample Car Load | 650kg |

| Number of Sprinkler Heads | 2 PC, one installed on the top of the spray sample top surface; One is mounted on the sides of the jet sample around the plane; |

| Jet Trajectory | Based on the principle of running S-shaped trajectory, a four-way servo motor is used to design a robotic arm to spray water on five sides. The spraying time of 60S per M2 meter is the basic reference test time, and the completion time of the entire trajectory can be set, which can be set between 150-300S (5 m2). When setting, the size can be entered according to the overall dimensions of the product. The robot system automatically completes the test trajectory for orderly testing. After the test, the arm returned to the original point of the device sound and light prompt. |

| Sample Arrangement | ① Use forklift to load and unload samples, forklift customers (suppliers to provide specifications), ② use truck to lift samples to move to the door of the equipment, and then ask the manual sample truck to push to the test space. After closing the door, the system prompts you to conduct a formal test. |

| Pure Water System | Provide 50L/H pure water equipment to provide water for heating, spray water recycling. |

| Power Source | AC380V three-phase five wire, 50Hz power: about 100KW (no load); Make a 120A air switch separately, the air switch should have wiring terminals, and the power line should be ≥50 square. |

| Water does not Circulate in the System | 1) The water source cannot be recycled (because the water source is dirty after the battery test, it is recommended to discharge the used water to the sewage tank). 2) If the user considers water recycling, please make the return pool and clear pool in advance; 3) Pipeline users are prepared in advance; 4) Water tank size: depth 2000× width 1000× height 1000mm. |

| Structural material | |

| Nozzle | 304 stainless steel hydraulic pipe |

| Cistern | 304 stainless steel |

| Electrical Control Accessories | International well-known brands such as Schneider and Omron are selected |

Technical Advantage for EV Charging Pile IPX9 High Temperature And Pressure Water Jet Test System

Heating system

The heating wire used in high frequency is very important in this system, the improper material selection of the heating pipe, short service life, easy to produce funnel short circuit phenomenon, for the user with high requirements is extremely inconvenient and distressed, and seriously affect the production and inspection progress. To this end, the company has developed the latest new type of ceramic heating rack, ceramic material high temperature resistance, good insulation, will not produce leakage short circuit phenomenon, the middle through the German imported heating wire, thick wire diameter, high temperature resistance, dry burning resistance. The quartz glass tube is inserted in the middle of the heating wire, and its important function is to prevent the heating wire from burning red, soft and falling, and produce the heating wire and the inner box metal contact resulting in short circuit and other fault phenomena. This technology is the first in China.

(Tank heating pipe)

High Temperature and High Pressure Water Pump Imported from Italy

High Temperature and High Pressure Electronic Flowmeter

Nozzle and Sample Holder

Water Pressure Calibration Sensing