Add to Cart

Description:

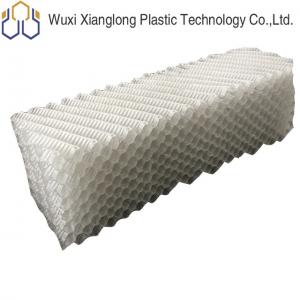

Cooling Tower PVC Fill, also called cooling tower infill film media. It is one of the most important components in cooling tower. It’s function is increase the exchange area of the gas and working fluid in order to achieve the requested cooling requirement. The working fluid was distributed onto the cooling tower PVC fill and spread into a thin film uniformly, by increasing the air-media interface and allowing waste heat to evaporate at an accelerated rate.

The heat resistance is the main factor influencing the cooling efficiency for the cooling tower PVC fill. And the quality of the raw material used for producing cooling tower PVC fill will influence the cooling tower fill's service time. always adapt the high quality cooling tower PVC fill for the cooling tower.

This type cooling tower PVC fill is designed for the factory-assem

bled counterflow cooling towers.

Tech Date | |

Sheet Width(mm) | 305/610mm |

Sheet Length | 1220/1830/2440mm/customized |

Thickness | 0.32-0.6mm/customized |

Sheet Spacing | 12/15/19/30mm |

Color | grey/white/black |

Material | PP/PVC/ CPVC |

*Cooling towers reject heat from water-cooled systems to the atmosphere. Hot water from the system enters the cooling tower and is distributed over the fill (heat transfer surface). Air is induced or forced through the fill, causing a small portion of the water to evaporate. This evaporation removes heat from the remaining water, which is collected in the cold water basin and returned to the system to absorb more heat. Each cooling tower line, although operating under the same basic principle of operation, is arranged a little differently.

*There are two main configurations of factory assembled cooling towers: crossflow and counterflow. In crossflow cooling towers, the water flows vertically down the fill as air flows horizontally across. In counterflow cooling towers, the water flows vertically down the fill as air flows vertically up.

Supply in industry

Cooling towers reject heat from water-cooled system to the atmosphere. Hot water from the system enters the cooling tower and is distributed over the fill (heat transfer surface). Air is induced or forced through the fill, causing a small portion of the water to evaporate. This evaporation removes heat from the remaining water, which iscollected in the cold water basin and returned to the system to absorb more heat. Each cooling tower line, although operating under the same basic principle of operation, is arranged a little differently.

About US