High Precision Injection Mold Moulded Precision Components For PET Preforms

Add to Cart

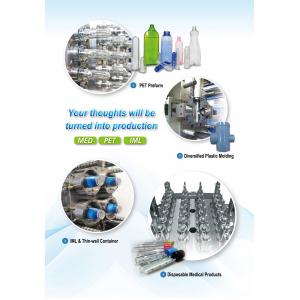

High Precision Injection Mold for PET Preforms / Automotive Parts

Introduction

FCS offers molds for the clients in addition to machinery manufacturing, and has been investigating in injection molding technology; (means/ tools to be used for analysis are CAD, CAM, CAE, FMS, FMC, etc.) for many years.

FCS established its product technical support team (Field Application Engineering Center ,FAE) which specializes in design & development for diversified precise molds. By way of analysis, processing, inspecting and measuring, FCS conducts integration and sales on various fields of injection molding and the most suitable products were worked out and have been adopted in the industry. FCS has become the most dependable provider of injection molding solution.

Diversified Molds Design / Manufacture / Automation / Customization

l PET Preforms

l Disposable Medical Products

l Housewares

l Thin wall Containers

l Automotive Parts

l PVC Fittings

Industrial Cooperation Advantage

In addition to providing one-stop shopping of equipment, FCS also have customized service offering technical transfer service and after-sales counseling to meet customer’s requirements (including injection molding machine, mold, peripheral equipment, molding conditions, and even raw material formulation).

The Cooperation Processes

1. Clients/Investors provide products expected to be produced, the product future development plan (estimated), and the capital budget.

2. FCS executes the blueprint plan, which contains production equipment list, technical guidance program, and production cost trial calculation.

3. Finally, both parties will confirm that if the contract is feasible. Otherwise, it will be adjusted again util the clients confirm.

Characteristic

- Design & Development of Diversified Precise Molds

- Mold flow analysis & optimized solution for mold design

- Specialized molding system: Sale & Integration (PET/IML/Medical series)

- Turnkey Solution Planning & Technology Transferring (operators’ training included)

Why choose us

Fu Chun Shin Machinery Manufacture Co., Ltd. (FCS) was founded in 1974. The name came from a lathe factory which Mr. Po Hsun Wang, the Chairman co-founded with his brothers at Fu Chun Road, Tainan, Taiwan. In 1978, FCS was successfully transformed into plastic injection molding machine manufacturer. In 1991 FCS moved to present location Guanmiao, to establish a global operation headquarters in response to the expanding scope of business, and so far it has set up two factories in Dongguan and Ningbo, mainland China. To pursue the better operational efficiency, in 2004, FCS received emerging stock approval from the Over-the-Counter Securities Exchange and becomes the only publicly traded professional injection molding machine manufacture in Taiwan.

FCS Group is implementing a philosophy to create high value added products, and to integrate the business strategies of globalization and diversification. In addition to the original business of injection molding machine R & D, manufacturing and sales, since 2001, FCS also branches out into Magnet cable business, 3C optoelectronics and materials technology industry. It is expected to lead the group heading to a much higher precision and high-tech areas, and to enhance FCS corporate value and international competitiveness in order to achieve the target of permanent continued operation.

WORLDWIDE TOP TEN

WE AIM TO BE IN THE LIST OF WORLDWIDE TOP TEN PLASTIC MACHINERY

MANUFACTURERS.

CUSTOMERS AS TOP PRIORITY

WE AIM TO BE THE BEST TRUSTWORTHY BUSINESS PARTNER OF OUR

CUSTOMERS.

REJOICE AT IMPROVEMENT

ALL STAFFS ENJOY DOING THEIR JOBS IN FCS, CHALLENGE THEMSELVES, AND

CONSTANTLY ENGAGE IN SELF-IMPROVEMENT.

PROFIT SHARING

WE SHARE OUR PROFITS WITH THE EMPLOYEES AND SHAREHOLDERS, AND

CREATE MUTUALLY BENEFICIAL WIN-WIN SITUATION FOR CUSTOMERS,

PARTNERS AND AGENTS.