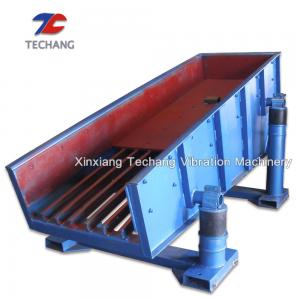

High Efficiency Vibratory Feeder With Adjustable Angle Rubber Springs

Add to Cart

High Efficiency Vibrating Feeder Price Used for Mineral , Coal , Cement , Stone

| Model | Capacity(t/h) | Feeding trough size(mm) | Working type | Particle size | Weight |

| GZG30-4 | 15 | 300×1000×160 |

| 120 | 110 |

| GZG40-4 | 30 | 400×1200×160 | 155 | ||

| GZG50-4 | 50 | 500×1200×160 | 190 | ||

| GZG60-4 | 80 | 600×1800×180 | 150 | 410 | |

| GZG70-4 | 100 | 700×1800×200 | 180 | 440 | |

| GZG80-4 | 200 | 800×2000×225 | 200 | 640 | |

| GZG90-4 | 300 | 900×1500×300 | 250 | 730 | |

| GZG110-4 | 400 | 1100×1500×300 | 900 | ||

| GZG130-4 | 500 | 1300×1500×400 | 350 | 1000 | |

| GZG70-6 | 80 | 700×1800×200 | 150 | 440 | |

| GZG80-6 | 160 | 800×2000×225 | 180 | 670 | |

| GZG90-6 | 240 | 900×1500×300 | 240 | 740 | |

| GZG110-6 | 320 | 1100×1500×300 | 940 | ||

| GZG130-6 | 500 | 1300×1500×400 | 400 | 1040 | |

| GZG150-6 | 780 | 1500×1800×560 | 2000 | ||

| GZG180-6 | 1000 | 1800×1800×500 | 600 | 2590 | |

| GZG200-6 | 1300 | 2000×2000×500 | 800 | 3700 |

3. Low noise, low power consumption, good performance of the regulator and nonexistence of material clashing circumstance.

High Efficiency Vibrating Feeder is realized by using a special vibrating motor to drive the feeding trough to make a cyclic linear reciprocating vibration in the oblique direction. When the vertical component of the acceleration of the vibration of the feed tank is greater than the acceleration of gravity, the material in the tank will be thrown up and jump forward according to the trajectory of the parabola, throwing and falling within 1/50 seconds, due to the continuous vibration of the vibration motor The vibration, the feed trough continuously vibrates, and the material in the trough continuously jumps forward to achieve the feeding purpose.

Advantages

1. Simple, stable, variable controller.

2. Vibrating force adjustable, easy to operation.

3. Low noise and power consumption.

4. Simple structure, easy to maintenance.

5. Low profile - minimum headroom.

6. Adjustable angle rubber springs.

7. Smoothly vibrating and long service life.

Vibrating Feeder Application

High Efficiency Vibrating Feeder is widely used in metallurgy, coal, chemical industry, building

materials, ceramics, food, light industry and other industries of

quantitative feeding, automatic batching, quantitative packaging

and automatic control feeding links.

1. Feeding scrap or glass cullet to furnaces.

2. Sprinkling toppings or coatings on food and dairy products.

3. Controlled flow of ingredients to mixing tanks.

4. Adding binders and carbons to foundry sand reprocessing systems.

5. Chemical additive feeding in the pulp and paper bleaching or

chip handling processes.

6. Feeding metal parts to heat treating furnaces.