Add to Cart

Industrial Mechanized Tomato Ketchup Production Line Aseptic Bag Package

Tomato processing plant Product description of

Tomato processing line can produce from fresh tomato to different kinds of final product. The popular products like tomato paste, tomato sauce & ketchup, tomato juice processing line, which produce from fresh tomato to the final product with aseptic bag in drum.

And the tomato paste in aseptic bag in drum can be further produced to tomato ketchup, sauces, juice and filled in sachet, stand-up pouch, metal can, PP container, bottle, gable top, etc.

The processing line mainly includes: fresh tomato receiving system, washing system, sorting system, crushing system, pulping and refining system, filtration system, concentrating system, sterilizing system, and aseptic filling system. Then we can get the tomato paste with aseptic bag in drum.

Gofun can not only provide the tomato processing equipment for the plant but also provide the one-stop solution from A to Z, which includes:

Main parameters of tomato production line

| Product name: | One-stop solution for tomato processing line |

| Fresh fruit input capacity: | 500kg per hour ~ 25 tons per hour |

| Raw material: | Fresh tomato, tomato paste |

| End product: | Tomato paste, tomato sauce or ketchup, tomato juice, etc |

| Final product Brix: | 28%~30%, 36%~38% |

| Final package: | Aseptic bag, Metal can, Sachet, Stand-up pouch, PP container, Plastic bottle, Glass jar, etc |

| The main material for machines: | Food grade SUS304 or SUS316 |

| Warranty: | 12 months after commissioning |

| Operator needed: | About 10~12 persons |

| Voltage: | 380V 50Hz/ 110V 60Hz/ 415V 50Hz |

| (adjustable to client's country standard) | |

| Advantages: | Energy-saving, high efficiency, water-saving |

Our Services for tomato processing plant

1. Technical support

2. Marketing suggestion

3. Final packing suggestion and design

4. Factory building and design

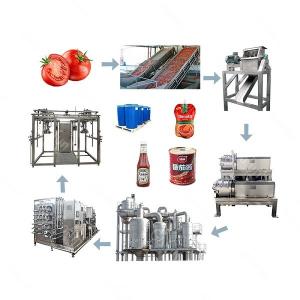

Flowchart of tomato paste/ sauce or ketchup processing

FRESH TOMATO ⇒ CONVEYOR ⇒ WASHING ⇒ SORTING ⇒ CRUSHING ⇒ PREHEATING ⇒ PULPER & REFINER ⇒ EVAPORATING ⇒ STERILIZING ⇒ ASEPTIC FILLING ⇒ STORAGE OR BLENDING

Final products & Package types for tomato project

Shanghai Gofun machinery company offers all kinds of the tomato processing line.

For the final package, it can be an aseptic bag, metal can, sachet, stand-up pouch, PP container, glass bottle, PET bottle, gable top, etc.

Key process of the tomato paste processing line

Now Shanghai Gofun machinery company will introduce the information of tomato paste processing line to show it works.

1. Storage or go blending

The finished product can be stored or used as the raw material to make the tomato sauce or ketchup.

2. Mixing and blending

The mixing and blending system is used for the mixing of the tomato paste or fruit pulp with water, sugar, cinder according to their formula.

3. Degassing & Homogenizing

Degassing machine is used to remove the bubbles and airs in the fruit pulp or mixed product. Homogenizer in food processing means to refine the material under the triple action of extrusion, strong impact and pressure loss expansion, so that the materials can be mixed with each other more evenly.

4. Pasteurizing

5. Different packages filling system

For weighing, filling, sealing of the final package.

6. Water Spray or Immersion Pasteurizing and Cooling

Water immersion type sterilizer is a pasteurization equipment specially designed for the filling or packaging of dairy products, juices, beverages, beer, food, condiments, medicines and other products. It is the ideal equipment for materials to achieve the purpose of extending shelf life through sterilization, different process designs can be carried out to meet the process requirements. According to user requirements, corresponding high-precision automatic control systems can be configured.

7. Air drying

Dry the metal can or sachet bag after the pasteurization.

8. Date printing

Print the production time or batch number on the can or bottle

9. Power Station of the whole plant

Main equipment: steam boiler, water cooling tower, air compressor, RO water treatment, ice water machine, etc.

Our Services for tomato processing plant

1. Technical support

2. Marketing suggestion

3. Final packing suggestion and design

4. Factory building and design