Fully Automatic Industrial Fruit Dryer / Fruit Dewatering Equipment

Add to Cart

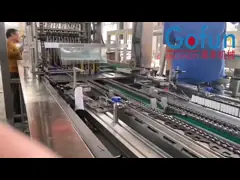

Fully automatic dried fruit and vegetable expanded system field installation

Company Information

Gofun Company provides the turn-key solution for not only the tomato paste production line but also the processing and packaging lines for apple, pear, peach, mango, and apricot and other fruits & vegetables, and has received wide spread praises from customers in both the domestic and overseas markets. The machines have already been exported to all over the world including the Asian countries, African countries, South American countries and even European and American countries. Gofun Company aim to create the outstanding food machinery and contribute to the world's agricultural industry. We sincerely committed ourselves to a brilliant prospect and mutual benefit relationship with all of the people and friends from Worldwide!

| Business Type | Manufacturer | Country | China |

| Main Products | Turn Key Solution for Fruit & Vegetable Processing and Packaging Complete Line | Capacity | 30 sets per year (whole line) |

| Established Year | 2009 | Main Market | Africa, South Ameria, Asia, Europe |

Characteristics

1.Dried apple slice is made from fresh apple. Procedure: peeling, coring, color protection, then to dry.

2.It keeps the color and taste of apple. Thickness of slice can be manufacture as your demand.

3.It has many advantages like low fat, low calorie and high fiber characteristics, crispy and delicious, good for health.

Flowchart

Dried Fruit and Vegetable Processing Line

DRYED FRUIT: FRESH FRUIT ⇒ CONVEYOR ⇒ WASHING ⇒ SORTING ⇒ DESTONING & CUTTING ⇒ BLANCHING ⇒ DEWATERING ⇒ VACUUM SUGAR DIPPING ⇒ DEWATERING ⇒ DRYING ⇒ PACKAGING

Processing Technology

S1. Slice: Select 7-8 ripe mangoes without decay. Then peeled, nucleated, cut into mango slices 3-5 mm thick;

S2. Color protection: Soak the mango slices in a color protection solution;

S3. Blanching: Put the color-protected mango slices into boiling water;

S4. Dipping sugar: Add mango slices and sugar liquid to a vacuum dip tank, vacuuming, dipping sugar, adjusting sugar content and vacuum impregnation;

S5. Pre-drying: drying mango slices;

S6. Softening, packaging: When the product reaches the moisture content required for drying, it is generally about 15% to 18%. Put the product in a closed container and let it soften for about 2 to 3 days to balance the water content of each part. The texture is soft and convenient for packaging.

Related Machine

Our Services

Gofun Machine is committed to building a world-renowned enterprise in the world's food, fruit and vegetable, dairy, beverage equipment production line turnkey project overall solution. The core components of our processing production line are basically imported or buy from domestic first-line brands. So the quality and equipment stability is relatively high, and our after-sales service has always been better in the industry both at home and abroad.

Shipping