Add to Cart

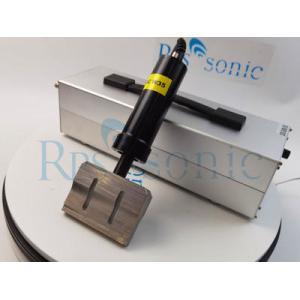

35Khz Ultrasonic Welding Equipment for Non-woven Fabric Welding Hygiene Industry

Ultrasonics is a clean and efficient method of joining or slitting

synthetic materials.While the initial investment is much more, the

long term benefits more than pay for itself.

Ultrasonic bonding uses high frequency sound to generate localized

heat through vibration and causes thermoplastic fibers to bond

together. Suppliers in the industry say the technology offers

several advantages.

Ultrasonics creates a mechanical bond rather than a chemical bond

created by adhesives. Mechanical bonds tend to hold up better in

extreme heat conditions such as may be incurred during

transportation in certain geographies. Being chemical-free is also

of potential benefit to the environment and end users with

sensitive skin.

Because ultrasonic bonding uses friction and pressure to bond

materials directly to each other, it makes the added cost of glue

and solvents, as well as the cost for added fixturing and the time

for glue to “set-up,” unnecessary. In addition, it eliminates glues

and solvents as potential sources of contamination along with the

need to clean and maintain glue and solvent application equipment.

Because ultrasonics can bond over a range of frequencies and with

varied levels of downforce, it also reduces the risk of damage to

even the most delicate nonwoven materials and filter media.

Kindly check the AMPLITUDE REFERENCE GUIDE for ULTRASONIC WELDING (in Microns (um)) table in the next page, you will find suit frequency for your application.

The benefits of ultrasonic welding are that it is much faster than conventional adhesives or solvents. The drying time is very quick, and the pieces do not need to remain in a fixture for long periods of time waiting for the joint to dry or cure. The welding can easily be automated, making clean and precise joints; the site of the weld is very clean and rarely requires any touch-up work. The low thermal impact on the materials involved enables a greater number of materials to be welded together.

Service and shipment