Add to Cart

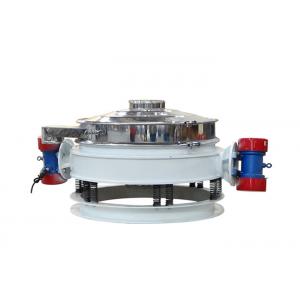

Instant Noodles Vibrating Sieve Separator Flow Thru Vibration Separation Machines

Product Introduction of Low Profile Flow-Thru Vibrating Safety Screeners for Instant Noodles:

Our low profile flow-thru vibrating safety screeners for instant noodles commonly referred to as safety screeners, control sieves, low-profile vibrating sieve, low profile separator, flow-thru separator, vibro flow-thru separator, inline screen, vibration in-line screen, inline vibro screen, vibrating control screener, direct discharge screen, low profile circular separator, straight-flow separator, flow through inline sifter, flowthru vibrating separator, flow-thru rotary vibrating separator, flow-thru vibro separator , flow- thru vibro screen, flour sifter etc.

It is suitable when safety sieving is required to assure the quality of both powder and liquid products, and are designed to provide a high sieving rate. Good material passes through and any larger unwanted material is retained above.

The flow-thru separator with side motor(s) (1~2 vibrating motors)

provide successful production of many products. Most often used

before packing to eliminate lumps and dirt and for fluid

filtration.

Thanks to ultrasonic mesh cleaning systems, we obtain high

performance and efficiency of sifting with small machines

dimensions. We design and build vibrating sifters for customer

requirements. Our experience and versatility of solutions allows us

to choose the right device for sifting the most difficult products

(flour, sugar, powdered sugar, starch, toners, cosmetic powders

etc.).

The construction and execution of vibrating screeners also allows

to use them for fluid filtration (chocolate, whey, starch, dyes,

plastic screenings etc.)

Some Important Information You May Concern About Low Profile Flow-Thru Vibrating Safety Screeners for Instant Noodles:

| Alternative Name | flow-thru separator, compact sieve, check screening machine, safety screener, control sieve, inline vibrating sieve etc. |

| Motor | single vibrating motor, dual vibrating motors (optional) |

| Height | 500mm or less (such as 350mm) |

| Mesh Debling System | ultrasonic deblinding system, bouncing balls |

| Layers of Screen | 1~2 layers of screens |

| Diameter | 600mm, 800mm, 1000mm, 1200mm, 1500mm, 1800mm, 2100mm |

| Discharge Port | the discharge port for fine particles are at the bottom of the machine |

| Purpose | suitable for materials safety screening with less oversize particles |

| Machine Shape | round, rectangular |

| Damping Spring | steel spring, rubber spring |

| Application | flour, starch, milk powder, additives, instant noodles, noodles, snacks, solid drinks etc. |

Technical Parameters of Low Profile Flow-Thru Vibrating Safety Screeners for Instant

Noodles:

| Model | 400 | 600 | 800 | 1000 | 1200 | 1300 | 1500 |

| Power | 0.1kw | 0.1kw | 0.1kw | 0.2kw | 0.2kw | 0.2kw | 0.4kw |

| Screen Diameter | 350mm | 550mm | 750mm | 920mm | 1005mm | 1120mm | 1420mm |

Note: the data above are for reference only, and our company reserves the right to modify the data.

Working Principle of Low Profile Flow-Thru Vibrating Safety Screeners for Instant Noodles:

This compact sieve adopt high-frequency vibration motor as the

excitation source, the materials do three-dimensional rotary motion

on the screen surface after into the system, flour and

agglomeration fully dispersed, rapid through mesh directly to the

lower silo. Foreign matter and impurities are separated and

discharged to the slag discharge port, the machine play the role of

“safety officer” on the production line.

Our low-profile vibrating control sieve can be used in the feed

system of front production line of instant noodles, noodles,

snacks, solid drinks etc., to separate the foreign matter from the

raw materials (flour, starch, milk powder, additives etc.). Because

it is in series with the system and automatically separates foreign

matter, it is honored as the “safety officer” on the food

production line. The flour sieve can replace the manual observation

of the foreign matter and check-up action.

Some Kinds of Low Profile Flow-Thru Vibrating Safety Screeners for Instant Noodles:

Features of Low Profile Flow-Thru Vibrating Safety Screeners for Instant Noodles:

1. Small and tight.

2. It can handle large quantities of material all in one go.

3. Because it generates three-dimensional vibration, the screening

effect is better, and the surface is kept continuously clean and

smooth.

4. The mesh screen can be easily replaced.

5. It can be operated with minimal supervision as the machine is

made to be easily used.

6. It can automatically eject oversized material particles that

didn’t fit the standard size requirements.

7. It is more suitable for the process of security screening of dry

materials with little to no large material particles.

8. It makes material particles flow in a direct-current like the

design.

9. This machine consumes less power compared to other brands’

rotary vibrating separators.

10. The machine has high-screening accuracy and can produce large

outputs at a time.

11. It is made from high-quality stainless steel to last years of

extensive everyday use.

Application of Low Profile Flow-Thru Vibrating Safety Screeners for Instant Noodles:

This flow-thru separator can be used by multiple industry companies

such as pharmaceuticals, food and spices, chemical, plastic,

fertilizer, wood, rubber, fodder, recycling and so on. It is most

often used for coarse and fine grind screening powders and material

particles in flour, laundry powder, starch, food additives,

chemicals etc.

The inline vibrating sieve machine also can separate foreign

objects that got included in raw powder materials. The food

industry companies mostly use the feeding system for the

manufacturing process.

Contact: Ms. Magie

E-mail: sale@aarealmachine.com

magiecn@gmail.com

WhatsApp/WeChat: 0086-15637361027

Website: https://www.aarealmachine.com