Add to Cart

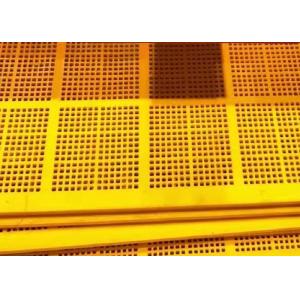

Reduce Change Out Time Individual Urethane Modular Screen For Aggregate And Quarry

Reduce Change out Time Inndividual Urethane Modular Screen for Aggregate and Quarry

WHY URETHANE?

• Long Wear Life: Polyurethane is ideal for highly abrasive and dry or wet applications, providing much longer wear life than traditional wire screen media.

• Exceptional Performance: Urethane offers excellent elasticity and impact absorption for increased screening efficiency.

• Low Cost Per Ton: Long life plus great productivity leads to significant reduction in total operating costs.

WHY MamBa PRODUCTS?

Specialized polymer formulas, combined with our experience in precision, open-cast manufacturing processes, result in urethane screening products that provide unmatched quality and performance.

Our urethane screen media delivers outstanding efficiency and wear life in even the harshest conditions.

Customized ,OEM and Free Mold Fee

Mam Ba., has expanded production facilities to once again offer a complete line of modular urethane screen panels and accessories. Our urethane screens provide long wear life, superior performance, low cost per ton, and reduced noise. We offer a number of panel fastening options, and we can fully design and build urethane screens to match your unique application.

Polyurethane Screen for mining mineral processing, grading, dehydration and other

screening machines replace metal sieve (mesh) of a new product.

Mainly used in coal, iron ore, copper, gold and other ores grading,

screening, dewatering and other places, is one of the components

necessary shaker sieve structure by polyurethane are divided into

four types: mosaic bolt Join layering connection screen hook

connection.

For example, layering connection type: Please place the sieve

screen surface, and then sieve the support beam to install. Should

generally be in the screening machine both sides of the upper sieve

plate, along with the width under the direction of the appropriate

material u type iron suitable distance strip drilling screw holes

and then bolt and tighten the underlying support beam, so that

prison sieve firmly set in the middle. Strip iron support beams and

the contact with the sieve is best to use rubber (can use old hose)

pad. Sieve the middle of the support beam above method can also be

installed here.

If the sieve plate is not required to install, you may shake it up

and down the screen surface, long-term friction and collisions with

steel support Liangfa Sheng, will seriously affect the life of

sieve.

Screen vertical and horizontal rules are made of high

wear-resistant polyurethane, wire article contains. Life than

traditional metal mesh 3-10 times higher. Unique structure,

suitable elastic and plastic strength, it reduced the card

blocking, while the second harmonic due to screen high-frequency

vibration section, but also reduce the sticky block. Practical hole

high screening efficiency.

Mesh with elastic tension on both sides hook, the overall light

weight, good flexibility, easy to transport storage, installation

and removal easy. Screen can effectively absorb the shock, reduce

noise, improve the working environment.

Special Specification can also be customized according to

customer's requirements.

Modular Polyurethane Screens Panels

| Modular PU Screen Panels | |||||

Overall Sizes mm | Aperture mm | Opening Angle | Height of screening Area mm | Thickness mm | Hardness |

| 305x305x30 | 0.3 | 11-25 | 11 | 30 | HS60-85 |

| 305x305x30 | 0.5 | 11-25 | 11 | 30 | HS60-85 |

| 305x305x30 | 0.75 | 11-25 | 11 | 30 | HS60-85 |

| 305x305x30 | 1 | 11-25 | 11 | 30 | HS60-85 |

| 305x305x30 | 1.5 | 11-25 | 12 | 30 | HS60-85 |

| 305x305x30 | 2 | 11-25 | 12 | 30 | HS60-85 |

| 610x305x45 | 0.3 | 11-25 | 11 | 45 | HS60-85 |

| 610x305x45 | 0.5 | 11-25 | 11 | 45 | HS60-85 |

| 610x305x45 | 0.75 | 11-25 | 11 | 45 | HS60-85 |

| 610x305x45 | 1 | 11-25 | 11 | 45 | HS60-85 |

| 610x305x45 | 1.5 | 11-25 | 12 | 45 | HS60-85 |

| 610x305x45 | 2 | 11-25 | 12 | 45 | HS60-85 |

Characteristics:

System screen modules are fixed to the substructure bars by means

of adapter slats, thus making it compatible to other types of

modular systems. there are system units with standard widths of 150

and 300 mm and flexible lengths of up to 1200 mm, all made of

highly wear resistant polyurethane.

Modular Panel Benefits

• Reduced running costs – only worn panels replaced

• Quick and simple installation and removal

• Firm connection of frame and panel

• Panels are reinforced internally and stay flat

• A wide range of apertures and panel thicknesses

• Flat screening surface ensures even feed distribution

• Variety of panel dimensions to suit customer needs

• Common sizes available ex stock

• Variations for improved efficiency readily available

Application:

Polyurethane Vibrating Screen is widely used for the classification of bulk material, such as

coal, minerals, coke, beans, etc. So it can be used in the

agriculture, chemical industry, minerals, quarry and smelting

industries.

Polyurethane vibrating screen can sort the wet materials, it can be

used in the water conservancy and hydropower and dewatering

industries.