Add to Cart

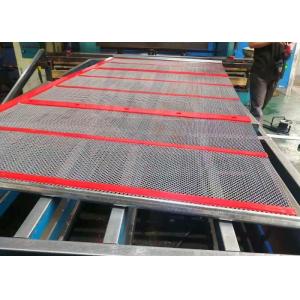

Mamba PU Strip High Tension Steel Wire Self Cleaning Screen Cloths

MamBa is committed to maintaining a leading position in global

screen media market. To uphold the commitment we make, we work

closely with our worldwide customers to make sure every screen is

featured by robust structure, long wear life and precise opening

size to help customers in increasing throughput while maintaining

high screening accuracy.

MamBa Self-cleaning screen Cloths is a specific type of screening

media made with multiple individual metal wires or polyurethane

material. Independent vibration of the wires is created at variable

frequencies to provide a good self-screening effect without

plugging the meshes. Self-cleaning screen is featured by less

plugging, increased wear life and higher screen efficiency in

contrast to conventional screen mesh. Due to these features,

self-cleaning screen has been increasingly popularized by customers

in many industries.

Self Cleaning Screen Cloths Main Parameter:

| Self Cleaning Screen Mesh | |

| Wire Diameter | 0.80mm-12.7mm |

| Aperture | 1.00mm-101.6mm |

| Opening Type | Shape D,V,S and H |

| Max width | 2500.00mm |

| Products Type | Flat Plates, Folding Hook,Modular |

| Material | High Carbon Steel Wire or Stainless Steel Wire. |

Self Cleaning Screen Cloths Opening Type:

Mamba strive for constant growth and innovation in mining and aggregate screening industry, aiming at offering the best product and service to our customers’ needs and creating additional value for their business.

Self Cleaning Screen Cloths

Self-cleaning screen is a specific type of screening media made with multiple individual metal wires or polyurethane material. Independent vibration of the wires is created at variable frequencies to provide a good self-screening effect without plugging the meshes. Self-cleaning screen is featured by less plugging, increased wear life and higher screen efficiency in contrast to conventional screen mesh. Due to these features, self-cleaning screen has been increasingly popularized by customers in many industries.

Tensioned self-cleaning screen

Tensioned self-cleaning screen is characterized by smooth and flat surface, its wear life is 3 times that of common woven wire screen. The individual wires in the self-cleaning screen vibrate independently at different frequencies, preventing mesh apertures from clogging while efficiently improving screening efficiency. The square-shaped aperture enables this self-cleaning mesh to be direct replacement for square woven mesh, having a good screening precision in most screening applications. Particularly, the tensioned self-cleaning screen has longer service life when compared to woven wire self-cleaning screen.

These self-cleaning screens also offer high open area, which makes them highly recommendable for applications requiring greater throughput. They are ideally suited for removal of the fines in operations like mine tailings treatment, efficiently flicking off the blinding issue.

Self Cleaning Screen Cloths Features& Benefits:

1.High screening efficiency

2.High go through rate

3.Less blinding, blocking or pegging

4.Less maintenance cost

5.Reduce operating cost and downtime

6.Various types of meshes.

Self-Cleaning Screen Cloths Application:

Self-cleaning screen made of woven wire cloth has an advantage of

higher temperature resistance which polyurethane self-cleaning

screen can not replace, it is typically used in sectors of road

construction or asphalt mixing. The individual steel wires vibrate

independently helping to avoid clogging or plugging while improving

screen efficiency. This type of self-cleaning screen is generally

applied in most common screening applications.