Titanium Clad Stainless Steel Tube Sheet 1.5mm - 238mm

Add to Cart

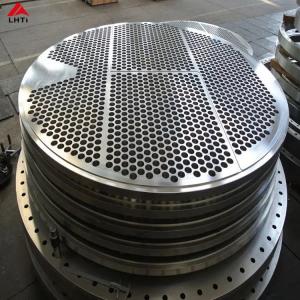

Titanium clad stainless steel tube sheet

The Titanium tube plate is drilling the pipes holes on the circular. Titanium steel Clad plate to be slightly larger than the outer diameter of the tube.

Item name : Titanium Tubesheet

Material: Gr1, Gr2, Gr5, Gr7,Gr12

Size &Standard: As per client drawing

Production Method: Forging,annealing and machining

Advantage: Excellent corrosion resistance ability

Packing: Plywood case

Application: Heat Exchanger, chemical equipment, Pressure Vessel,

filter devices, etc.

Application

Boilers and pressure vessels;Petroleum;Chemical industry;Shipbuilding;Pharmaceutical;Metallurgy;Machinery;Food production ETC.

Product performance

● Low Density and High Strength

● Excellent Corrosion Resistance

● Good resistance to effect of heat

● Excellent Bearing to cryogenic property

● Nonmagnetic and Non-toxic

● Good thermal properties

Titanium composite steel plate tube-sheet is a single or double-sided composite plate made of ordinary grade TA1 or TA2 (composite metal) and carbon steel or alloy steel by explosion, explosion + rolling or hot rolling. Titanium metal has excellent corrosion resistance, widely used in flue gas desulfurization equipment, power plant chimneys, chemical reactors, heat exchangers, pressure vessels, etc. But its disadvantage is high cost, titanium composite steel plate tubesheet has the corrosion resistance of titanium metal and the structural strength of steel, can greatly reduce the project cost.

At present, the production method of titanium composite steel tubesheet is as follows:

1. Weld compound 2. Rolling compound 3. Explosive welding 4. Explosive welding + rolling

Baoji Lihua uses explosive welding and rolling and combines the two processes. This method can overcome the disadvantages of small area and complex rolling process of explosive composite plate, give full play to their respective advantages, and produce titanium steel composite plate with large area and small thickness. It is more efficient and cheaper.

| Technological parameters and shear strength of explosive welding of Titanium clad stainless steel plate tube sheet 1 | ||||||||||||

| Cladding materials | Base materials | h0/ mm | Wg/ (g.cm-2) | Bond strength/MPa | 1 | 2 | 3 | 4 | Average | Remark | ||

| Metal | δ1/ mm | Metal | δ2/ mm | |||||||||

| Titanium | 3 5 | Stainless steel | 18 | 5 6.5 | 1.4 1.6 | σt | 293 | 200 | 392 | 179 | 266 | The substrate is generally polished. |

| σf | 247 | 208 | 113 | 92 | 165 | |||||||

| σt | 447 | 530 | 460 | 441 | 444 | The substrate is polished. | ||||||

| σf | 403 | 200 | 363 | 322 | ||||||||

| σt | 139 | 105 | 203 | 205 | 163 | The substrate is generally polished. | ||||||

| σf | 231 | 345 | 286 | 287 | 285 | |||||||

| σt | 407 | 410 | 263 | 407 | 372 | The substrate is polished. | ||||||

| σf | 498 | 571 | 513 | 527 | ||||||||

| Losive welding of Titanium clad stainless steel plate tube sheet 2 | ||||||||||||

| Cladding materials | Base materials | h0/ mm | Wg/ (g.cm-2) | Bond strength/MPa | 1 | 2 | 3 | 4 | Average | Remark | ||

| Metal | δ1/ mm | Metal | δ2/ mm | |||||||||

| Titanium | 3 5 | Stainless steel | 18 | 5 6.5 | 1.4 1.6 | σt | 392 | 87 | 240 | 18 | The substrate is generally polished. | |

| σf | 345 | 92 | 157 | 12 | ||||||||

| σt | 530 | 279 | 402 | 5 | The substrate is polished. | |||||||

| σf | 403 | 200 | 321 | 3 | ||||||||

| σt | 339 | 60 | 230 | 18 | The substrate is generally polished. | |||||||

| σf | 287 | 149 | 233 | 11 | ||||||||

| σt | 571 | 513 | 541 | 2 | The substrate is polished. | |||||||

Detailed images:

Titanium tubesheet used in heat exchanger:

About our company:

Packing and shipping: