Add to Cart

| Description | Factory Price Aluminium Tubing Profile And Aluminum extrusion Pipe |

| Material Thickness(t) | 0.8-14 mm |

| Materiral | aluminum alloy 6063-T5 |

| Annealing Treatment | T3-T8 |

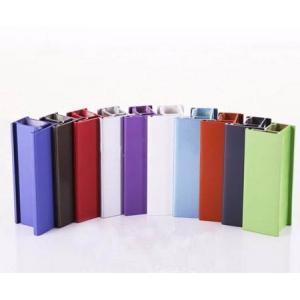

| Color | Silver White ,Bronze , Champagne, Black, (RAL series)etc. |

| Surface Treatment | anodized, powder coated, electrophoresis, wood grain, polished and etc |

| Shape | Square, Round, Flat, Oval, and according to customer's drawing. |

| Length | Normal length=6m or in customer's order |

| Usage | Building, Production Line, Decoration, Industrial, Transportation, Door and window, etc. |

| Package | 1. Pearl cotton foam for each profile; 2. Wrap with shrink film exterior; 3. Packed according to customer request. |

| Advantages/Features | Providing colorful products with various mechanical performances to adapt all kinds of architectural styles |

The density of aluminum profiles is only 2.7 g/cm3, which is about a third of the density of steel, copper or brass (7.83 g/cm3, 8.93 g/cm3). In most environmental conditions, including air, water (or brine), petroleum chemistry, and many chemical systems, aluminum shows excellent resistance to corrosion.

Electrical conductivity

The aluminum profile is often chosen because of its excellent conductivity. On the basis of weight, aluminium is nearly twice as conductive as copper.

Thermal conductivity of rate

The thermal conductivity of aluminum alloy volume rate is about 50-60% of copper, the manufacturing heat exchangers, evaporators, heating appliances, cooking utensils, as well as the automobile cylinder head and radiator are favorable.

The ferromagnetic

The aluminum profile is non-ferromagnetic, which is an important feature for the electric and electronic industries. Aluminum profiles are not self-igniting, which is important for applications that involve loading and unloading or touching inflammable and explosive materials.

Can machine processability

The machinability of aluminium profile is excellent. In deformation and aluminum casting aluminum alloy, as well as in the alloy after output with the various states, the change of the machining features is quite big, this will require a special machine tool or technology.

formability

Specific tensile strength, yield strength, malleability, and corresponding processing hardening rate dictate the change in the amount of deformation allowed.

Why Choose us ?

1. We can make 0.4mm ultrathin material

2. Good wear and corrosion resistance

3. Surface Finish: Anodized, Powder Coating or as your requested

4. Smoothness, attractive and elegant looking to meet your

perferences

5. We previde One Package Service: Extruding,Milling, Drilling,

Precise Cutting,Special surface treatment and packing,etc

Xuancheng Huilv Aluminum Industry Co., Ltd. was established in

2009. It has a complete industrial chain system of profile

extrusion, surface treatment, aluminum product design and

development, production and installation, with an annual production

capacity of 50,000 tons. The company occupies more than 200,000 M².

Our aluminum products and deep finishing capabilities rank among

the best in the industry.

With more than 10 years of industry experience, we keep innovating

continuously and obtain more than 100 research achievements and

many national invention patents successively, and won the honors of

"National Exemption Inspection", "Anhui Famous Brand" and "Anhui

Export Famous Brand". Based on the advanced technical equipments

and scientific management systems, backed by a complete industrial

chain and large-scale production, with support of high quality

aluminum products output service, our aluminum products are sold

very well in the domestic and overseas markets, and we are always

making efforts to be an international first-level aluminum

manufacturer.