Add to Cart

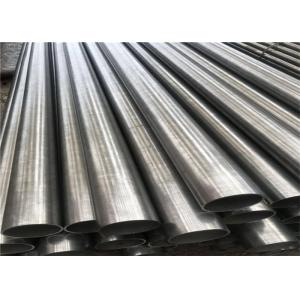

Annealed Welded Steel Tubes Oiled Painted Black Anneal Round Tube Black

Production Information

Size Range:

| Production | Outside Diameter | Wall Thickness |

| Boiler Pipe | 6.00mm to 630mm | 0.5mm to 52mm |

Final Finishing

Solution Annealed & Pickled / Bright Annealed.

Some of the quality tests carried out by us includes:

| Corrosion Test | Conducted only when specially requested by the client |

| Chemical Analysis | Test done as per required quality standards |

| Destructive / Mechanical Testing | Tensile | Hardness | Flattening | Flare | Flange |

| Reverse-bend and Re. flat tests | Carried out in full compliance with relevant standards & ASTM A-450 and A-530 norms, which ensures trouble-free expansion, welding & use at customers end |

| Eddy Current Testing | Done to detect homogeneities in subsurface by using Digital Flaw-mark Testing System |

| Hydrostatic Testing | 100% Hydrostatic Testing carried out according to ASTM-A 450 norms for checking tube leakage, and biggest pressure we can support 20Mpa/7s . |

| Air Under Pressure Test | To check any evidence of air leakage |

| Visual Inspection | After passivation, every single length of tubes & pipes is subjected to thorough visual inspection by trained staff for detecting surface flaws & other imperfections |