Double Bottle Holders Line 300BPH 3 Gallon Filling Machine

Add to Cart

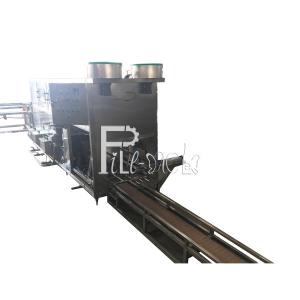

Double bottle holders line Gallon filling plant for 3 gallon barrel bottling

Equipment list:

| 1.1 | Semi-auto de-capper and washer | BS-1 | 900*900*1250 | 1set |

| 1.2 | Monoblock rinser-filler-capper with full SUS304 | QCF-300 | 3400*1000*1750 | 1set |

| 1.3 | Output belt conveyor with motor | / | 2M | 1set |

| 1.4 | Checking Light | CL-1 | 1000*100*450 | 1pc |

| 1.5 | Label shrink tunnel | / | 600*600*1000 | 1set |

| 1.6 | Solid Ink Roll Coding Machine | FP-380F | 440*345*300 | 1set |

The Gallon filling plant includes Semi-auto de-capper and washer, Monoblock rinser-filler-capper,Roller conveyor, Label shrink tunnel, Checking Light,Solid Ink Roll Coding Machine

1, Semi-auto de-capper and washer

Worker put used jar in right side of de-capper position, with the neck inserting into the hole, worker foot press pedal to release cap off neck; And then worker need to take the jar to insert into left side of the machine-washing position.

After the jar putting in, the window need to be closed. Then the washer will be started by itself.

During washing, the inner brush inside jar and Washing time is pre-settled, the machine will stop when time finish.

Heating function could be switched on/ off as client’s needing.

Parameters:

Power: 1.12KW without heating, 2.12KW with heating

Plate thickness: 1MM

Machine cube size: 25*25MM

Cube thickness: 1.5CM

Recommended Spare parts list:

| NO. | Items | Qty. | Price(USD) |

| 1 | inner brush | 1pcs | For free |

| 2 | outer brush | 3pcs | 22 |

| 3 | bucket neck brush | 3pcs | |

| 4 | bucket bottom brush | 1pcs | |

| 5 | spare buttons for control | 1suit | 7 |

| 6 | Air switch | 1pcs | 17 |

| 7 | Contactor | 1pcs | 14 |

| 8 | Foot pedal | 1pcs | 12 |

2, Monoblock rinser-filler-capper with full SUS304

The Gallon filling plant is integrated washing filling and capping together.

It is ideal machine to produce barrel water.

The whole Gallon filling plant is using stainless steel 304 ,rot resistant,can be cleaned easily.

Main electric parts are all branded. Air channel system use Air TAC brand product.

The Gallon filling plant is with compact construction,will occupy small room,working efficiency is high.

Only need 2 operators to control, is a good choice for factory to choose.

The Gallon filling plant set up do not need plug floor screw,after case taking off,set the machine on the flat floor,and then adjust stand height and adjust all stand pressure to be average.

After the Gallon filling plant is set up well, get in through water pipe, drain pipe and power , air power.

Working process:

Barrel filling unit can be divided into 3 steps: washing, filling and capping, total 36 working stations,working process as below:

1)Set empty barrel mouth to barrel seat, empty barrel will be washed during headstand situation,4 working station for barrel inserting.

2)Washing process will be divided into 4 steps:

1, hot alkali water washing 2,thimerosal washing; 3,clean water washing,4,pure water washing.Every washing step is set to 8S,after washing,there will be 10S for dripping.

3)The barrel after washing will move down 45 degree through the passing chain and will passing out chain and turn over 45 degree by barrel lift cylinder to filling position for filling.

4)Filling value will driven by cylinder to insert into barrel and start to fill, filling time is controlled by PLC, and filling time is adjustable by control panel according to filling liquid surface.

After filling, the extra water will back to pure water tank by automatic vent,it can reduce water consumption.(water tank is not included)

5)After filling process finish,the filled barrel will be pushed to capping position by barrel stop cylinder,the whole process finish till now.

Spare parts for free:

Sealing ring for filling valves*1suit

Recommended Spare parts list:

| NO. | Items | Qty. | Price(USD) |

| 1 | Sealing ring for filling valves | 1suit | For free |

| 2 | Bucket holder | 2pcs | 6.8 |

| 3 | Cap pressing mould | 1pcs | 5 |

| 4 | Air switch | 1pcs | 17 |

| 5 | Contactor | 1pcs | 14 |

| 6 | Solenoid valve | 1pcs | 27 |

Parameters:

Cylinder: Air tech-Taiwan

Magnetic valve: Air tech-Taiwan

Rising pump-filling pump: Nanfang

Motor: TWT Taiwan

PLC: Mitsubishi Japanse

Power: 5.3KW

Dimension: 3400*1000*1750mm

Weight: 500kg

4steps rinsining process, 3 storage tank with soap water, sterilizer water and recycling water

Temp controller for hot soap water tank

3, Belt conveyor for output 4, Checking light 5, Label shrink tunnel

1.6, Solid Ink Roll Coding Machine

Description:

The use of photoelectric integration technology, advanced solid ink wheel, has the excellent performance of instant printing and instant dry, which is not easy to erase. The machine is advanced in design, precise in manufacturing, stable in operation, longitudinally controlled in position by electronic control, arbitrarily adjustable, photoelectrically controlled printing actions and counts, and the number of printable sheets can be set.

Applicable to the surface indentation or color printing production date, product batch number, expiration date, inspection qualification, etc. of paper boxes, labels, tags, certifications, etc., with automatic sorting, automatic counting, random positioning, preset printing times, Indentation is clear, color is optional, printing speed is fast, instantaneous printing instant dry, loss and other advantages.