Add to Cart

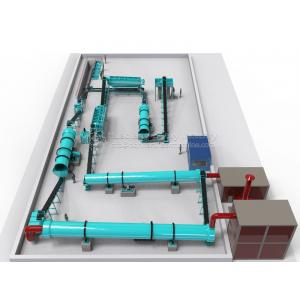

Low Dust Low Power Consumption NPK Fertilizer Production Line

Description of Low Dust Low Power Consuption NPK Fertilizer Production Line Processing Equipment

One well-known NPK fertilizer production in china, Size NPK fertilizer production is aimed to the massive excrement and sewage which have the extremely exceeded harmful elements caused by poultry factory, using efficient sterilization and deodorization technology for the putrefaction of liquid and solid to make compound fertilizer through efficient excrement ageing fermentation, raw material mixture, particle producing, drying, packing. This line could be applied to Chicken manure, pig manure, sheep manure, cow manure, annual output 10-300 thousand tons.

The Main Equipment of Low Dust Low Power Consumption NPK Fertilizer Production Line Equipment as follows:

| Main Equipment | Function | |

| 1 | Automatic Batching System | Raw material of different proportions with be automatically weighed

for batching. |

| 2 | Crusher Machine | Crush and break the cake material. |

| 3 | Mixing Machine | Mix different powders evenly, If necessary, add water. |

| 4 | Rotary Drum Granulator | After crushing and mixing, the powders granulation by the rotary

drum granulator. |

| 5 | Rotary Dryer Machine | Dry fertilizer granules to low moisture by hot air. |

| 6 | Rotary Cooler Machine | Cool fertilizer granules to normal temperature. |

| 7 | Screening Machine | Screen out the required size from fertilizer granules. |

| 8 | Coating Machine | Coat colour, anti-blocking agent, liquid etc on fertilizer

granules. |

| 9 | Belt Conveyor | Belt Conveyor is a kind of machine to transfer the material continuously. The belt works under the effect of the frictional force. |

| 10 | Packaging Machine | Package fertilizer granules into bags. |

Features of Low Dust Low Power Consumption NPK Fertilizer Production Line Processing Equipment

1. The fertilizer making machines are based on advanced and mature technology, high production efficiency, low labour intensity, low investment cost.

2. The whole fertilizer making process is computer central controlled, process art is accurate and easy to operate.

3. The product of NPK fertilizer granulation process, each quality index accords with national standards GB15063-2001 for fertilizer. At the same time, waste gas and wastewater discharge meet with the national quality requirements.

4. The NPK fertilizer production line capacity ranges from 10,000 tons to 300,000 tons per year.

Advantages of Low Dust Low Power Consumption NPK Fertilizer Production Line Processing Equipment

1. NPK fertilizer granules production line equipped with advanced

fertilizer manufacturing technology, this npk compound fertilizer

production line can complete npk fertilizer granulation all in one

process.

2. NPK fertilizer production line adopts advanced rotary drum

granulator, the granulating ratio is up to 90%, high intensity of

granules,

3. The inner cylinder body adopts high-quality rubber plate lining

structure which prevents the raw material from sticking on the

plate.

4. NPK fertilizer granules production line has wide adaptability of

raw materials, suitable for npk compound fertilizer, chemicals,

mining, granulation, agriculture and so on.

5. NPK fertilizer production line with high-quality, stable

performance, anti-corrosion and wear-resistant materials

components, abrasion-proof, low energy consumption, long service

lifespan, easy maintenance and operation, etc.