Add to Cart

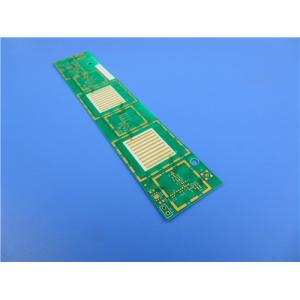

This is a 6-layer high-performance PCB constructed with Rogers RO4350B laminate, a woven glass-reinforced hydrocarbon/ceramic composite engineered for high-frequency applications. The PCB integrates advanced material properties with precision manufacturing to deliver exceptional electrical performance, structural stability, and cost-effectiveness for RF and microwave systems.

PCB Specifications

| Parameter | Technical Details | Engineering Significance |

| Base Material | Rogers RO4350B (woven glass reinforced hydrocarbon/ceramic composite) | Combines PTFE-like electrical performance with epoxy/glass manufacturability, ideal for high-frequency applications |

| Layer Count | 6-layer rigid configuration | Supports complex signal routing with dedicated power/ground planes for EMI control |

| Board Dimensions | 110mm × 80mm ±0.15mm | Ensures dimensional stability for automated assembly and enclosure fitting |

| Minimum Trace/Space | 4/4 mils | Enables high-density routing with minimal crosstalk in RF circuits |

| Minimum Hole Size | 0.3mm | Accommodates fine-pitch components while maintaining structural integrity |

| Vias | 455 total; blind vias (L1-L4, L5-L6); 20μm plating thickness | Reduces signal path length and minimizes reflections in high-speed designs |

| Finished Thickness | 1.6mm | Provides optimal balance between structural rigidity and weight |

| Copper Weight | 1oz (35μm) for inner and outer layers | Ensures low resistance while maintaining high-frequency performance |

| Surface Finish | Electroless Nickel Immersion Gold (ENIG) | Delivers excellent corrosion resistance, solderability, and stable RF contact resistance |

| Silkscreen | White on both top and bottom layers | Facilitates component identification and assembly verification |

| Solder Mask | Green on both top and bottom layers | Protects copper traces while providing environmental resistance |

| Quality Assurance | 100% electrical testing (continuity, isolation, and impedance) | Verifies compliance with design specifications prior to deployment |

Stack-up Configuration

The 6-layer stack-up is engineered for optimal signal integrity and controlled impedance:

| Layer Sequence | Material/Component | Thickness | Function |

| 1 | Copper Layer 1 | 35μm | Primary signal layer for high-frequency traces |

| 2 | Rogers RO4350B Core | 0.254mm (10mil) | Dielectric layer with controlled Dk for impedance management |

| 3 | Copper Layer 2 | 35μm | Ground plane for Layer 1 signals |

| 4 | Prepreg RO4450F (x2) | 0.2mm | Bonding layer with compatible dielectric properties |

| 5 | Copper Layer 3 | 35μm | Power distribution layer |

| 6 | Rogers RO4350B Core | 0.508mm (20mil) | Central dielectric providing isolation between planes |

| 7 | Copper Layer 4 | 35μm | Secondary ground plane |

| 8 | Prepreg RO4450F (x2) | 0.2mm | Intermediate bonding layer |

| 9 | Copper Layer 5 | 35μm | Secondary signal layer |

| 10 | Rogers RO4350B Core | 0.254mm (10mil) | Bottom dielectric layer |

| 11 | Copper Layer 6 | 35μm | Auxiliary signal routing layer |

RO4350B Material Properties

Rogers RO4350B laminate exhibits key characteristics that enhance PCB performance:

| Property | Value | Technical Impact |

| Dielectric Constant (Dk) | 3.48 ±0.05 @ 10GHz/23°C | Ensures consistent signal propagation with minimal variation |

| Dissipation Factor (Df) | 0.0037 @ 10GHz/23°C | Minimizes signal loss in high-frequency applications |

| Thermal Conductivity | 0.69 W/m/°K | Facilitates efficient heat dissipation from active components |

| CTE (X/Y/Z) | 10/12/32 ppm/°C | Matches copper expansion to reduce thermal stress and via fatigue |

| Glass Transition Temperature (Tg) | >280°C | Maintains stability during high-temperature processing and operation |

| Water Absorption | 0.06% | Prevents performance degradation in humid environments |

| Flammability Rating | UL 94 V-0 | Enables use in applications requiring fire safety compliance |

Manufacturing and Quality

Artwork Format: Gerber RS-274-X, ensuring compatibility with standard PCB fabrication processes

Quality Standard: IPC-Class-2 compliance, guaranteeing reliable performance for general electronics applications

Processing Compatibility: Compatible with standard FR-4 manufacturing workflows, eliminating the need for specialized processing required by PTFE-based materials

Application-Specific Advantages

The PCB's design and material selection make it particularly suitable for:

Cellular Base Stations: Low dielectric loss ensures efficient signal transmission in power amplifiers and antenna systems

Automotive Radar: Dimensional stability and thermal performance withstand harsh automotive environments

RF Identification Systems: Controlled impedance characteristics support reliable wireless communication

Satellite LNBs: Tight Dk tolerance enables precise phase matching in frequency conversion circuits

Availability

This PCB is available for worldwide shipping, supporting global project requirements.

Conclusion

This 6-layer RO4350B PCB combines advanced material properties with optimized stack-up construction to deliver exceptional performance in high-frequency applications. Its balance of electrical performance, manufacturability, and cost-effectiveness makes it an ideal solution for demanding RF and microwave systems.