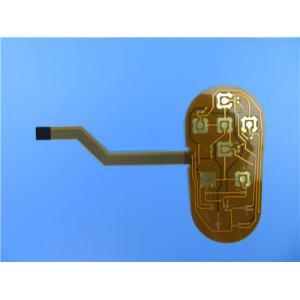

Polyimide 25um 0.2mm Flexible PCB Board For Capacitive Touch Screen

Add to Cart

2 Layer Flexible Printed Circuit FPC Built On Polyimide With PI Stiffener and Immersion Gold for Capacitive Touch Screen

(Flexible printed circuits are custom-made products, the picture and parameters shown are just for reference)

General description

This is a type of flexible printed circuit for the application of keypad. It’s a 2 layer FPC at 0.2mm thick. The base laminate is from ITEQ, It’s fabricated per IPC 6012 Class 2 using supplied Gerber data. Polyimide stiffener is applied on the inserting part.

Parameter and data sheet

| Size of Flexible PCB | 120.18 X 30.28mm |

| Number of Layers | 2 |

| Board Type | Flexible PCB |

| Board Thickness | 0.20mm |

| Board Material | Polyimide 25µm |

| Board Material Supplier | ITEQ |

| Tg Value of Board Material | 60℃ |

| PTH Cu thickness | ≥20 µm |

| Inner Iayer Cu thicknes | N/A |

| Surface Cu thickness | 35 µm |

| Coverlay Colour | Yellow |

| Number of Coverlay | 2 |

| Thickness of Coverlay | 25 µm |

| Stiffener Material | Polyimide |

| Stiffener Thickness | 0.2mm |

| Type of Silkscreen Ink | IJR-4000 MW300 |

| Supplier of Silkscreen | TAIYO |

| Color of Silkscreen | White |

| Number of Silkscreen | 1 |

| Peeling test of Coverlay | No peelable |

| Legend Adhesion | 3M 90℃ No peeling after Min. 3 times test |

| Surface Finish | Immersion Gold |

| Thickness of Nickle/Gold | Au: 0.03µm(Min.); Ni 2-4µm |

| RoHS Required | Yes |

| Famability | 94-V0 |

| Thermal Shock Test | Pass, -25℃±125℃, 1000 cycles. |

| Thermal Stress | Pass, 300±5℃,10 seconds, 3 cycles. No delamination, no blistering. |

| Function | 100% Pass electrical test |

| Workmanship | Compliance with IPC-A-600H & IPC-6013C Class 2 |

Features and benefits

Excellent flexibility

Reducing the volume

Weight reduction

Consistency of assembly

Increased reliability

The end can be whole soldered

Low cost

Continuity of processing

Offer small quantity, prototypes and production.

DDU Door to door shipment with competitive shipping cost.

Applications

Capacitive touch screen / panel, industrial control interphone, Consumer electrostatic Bracelet soft board

Components of a flexible circuit

A flexible circuit consists of copper foil, dielectric substrate+ coverlay and adhesive.

Copper foil is available in two different types of copper: ED Copper and RA copper.

ED copper is an electro-deposited (ED) copper foil produced in the same way as the copper foil used for rigid printed circuit boards. This also means that the copper is “treated”, i.e., it has a slightly rough surface on one side, which ensures a better adhesion when the copper foil is bonded to the base material.

RA copper is a rolled and annealed copper foil produced from electrolytically deposited cathode copper, which is melted and cast into ingots. The ingots are first hot-rolled to a certain size and milled on all surfaces. The copper is then cold-rolled and annealed, until the desired thickness is obtained.

Copper foil is available in thickness of 12, 18, 35 and 70 μm.

The most common available for dielectric substrate and coverlay is polyimide films. This material can also be used as coverlay. Polyimide is best suited for flexible circuits because of its characteristics as stated below:

1. High temperature resistance allows soldering operations without damaging the flexible circuits

- Very good electrical properties

- Good chemical resistance

Polyimide is available in thicknesses of 12.5, 20, 25 and 50 μm.

Base laminates for rigid printed circuit boards are copper foils laminated together with the base materials, the adhesive coming from the prepreg material during lamination. Contrary to this is the flexible circuit where the lamination of the copper foil to the film material is achieved by means of an adhesive system. It is necessary to distinguish between two main systems of adhesive, namely thermoplastic and thermoset adhesives. The choice is dictated partly by the processing, and partly by the application of the finished flexible circuit.