E0 12mm Hardboard Pegboard Sheets For Room Decoration

Add to Cart

Factory Direct Sales Wholesale Perforated MDF Boards for Noise Reduction

Perforated MDF board has excellent echo reduction effect. The MDF acoustic panel is a wood panel with holes, there are

two types of perforated MDF acoustical sound board: one is drilling hole until the end, the other is large and small holes, which

means that the diameters of the holes on both sides of are not the same.

Product Paramenters

Material | HDF/MDF/ Hardboard |

| Size | 1000*2000 mm,1200*2400mm or customized |

| Thickness | 1-18mm |

| Hole Distance | >=3mm |

| Hole Diameter | 4mm~20mm |

| Color | White, Black, Browm, etc/ soild color/ wood grain color |

| Surface | Melamine paper/ painting/PVC/ UV /PU Paper |

| Grade | E0, E1, E2 |

| Delivery Time | 15 days |

| Usage | To accept pegs or hooks to support various items |

Perforated MDF

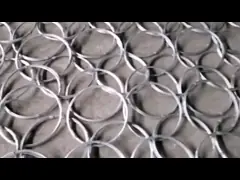

As well as flexible MDF we also stock a range of Perforated MDF

board in 1220 x 2440mm standard size, in 4mm, 6mm, 9mm, 12mm, and

15mm thicknesses.

Our perforated MDF boards are machine routed in a number of highly attractive designs where air and light is required to pass

through the panels. It has a pre sanded finish and can be coated with virtually any type of paint or varnish for superb and

visually appealing results.

Perforated MDF Applications

It is ideal for covering ugly radiators while allowing warm air to

circulate freely.

It is also ideally suited to the making of screens and panels and can make an attractive decorative statement in any room or

fitted furnishing. Our Perforated MDF panels allow air to circulate and the formation of beautiful patterns of light and shade

that when strategically placed near a light source, can totally transform the atmosphere of any room.

Perforated MDF can also be used to make screens and dividers and can add a decorative touch to furniture building. In fact this

material has so many potential applications in design there seems to be almost no limit to the creative applications and projects

these perforated panels can offer, with a bit of imagination.

MDF Acoustic Wall Panel Installation Method

(1) Light steel keel system for perforated wood board

(2) Wood batten system

Pre-installation Requirements:

1. The installation site must be dry, and the minimum temperature

should not be less than 10 Degrees Celsius.

2. The maximum humidity change after perforated board installation

should be in the range of 40% -60%.

3. The installation site must meet the above specified humidity

standards at least 24 hours prior to installation.

4. Perforated MDF board must be placed in the installation site for

48 hours, so that the board can adapt to the indoor

environment.

5. If you use wood keel, the distance from wood keel surface to the

base is generally 50cm in accordance with the specific

requirements.

6. If there is a need for filler in the keel gap, make sure that it

does not affect the installation of perforated MDF board or

perforated ceiling tile.