Add to Cart

Self Piercing Busbar Riveting Machine Aluminum Profile Assembly Machine

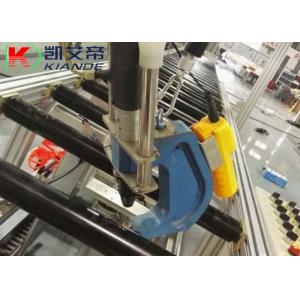

Self Piercing Riveting System for Automatic Busway Production Aluminum Profile Assembly Machine

The applications and features of self-piercing riveting systems are always similar. On the basis of this knowledge we created three standard configuration variants, which fulfil the majority of requirements. Our two servo motor-driven self-piercing riveting systems are designed for stationary or mobile use on a robot. Part variants, complexity, vulnerabilities, maintenance intensity and costs are therefore minimised, which reduces the need for special rivet systems – all for your benefit!

Advantages of self-piercing riveting include:

Equipment data on self-piercing riveting machine

| No. | Parameters |

| Model | KD-MJQ-2 |

| Max. Pressure | 250MPa |

| Oil Pipe Length | 10000mm |

| Oil Tank Capacity | 50L |

| Gun Head Stroke | 50mm |

| Aluminum Thickness | 3mm+3mm |

| Iron Thickness | 1.5mm+1.5mm |

| Power | 380~415VAC 50~60Hz 4.5kW |

Function introduction

Self-piercing riveting machine, also called riveting gun, is applied for busbar assembly. It can be customized according to different busbar housing. Before riveting, operator does not need to drill the hole. Machine can realize self-piercing riveting by its pressure and rivet structure. Working principal is as below.

Features:

1, The supercharger drives the split cylinder as the riveting power

source, which has the characteristics of low noise, low energy

consumption and no pollution.

2, The servo system controls the rivet clamp and the left and right

movement, to realize the two sides are simultaneously riveted by

the forward movement and the stop action of the roller.

3, The discharge line has a lateral removal function.

4, The busbar casing is no more than 3 meter length.

5, Feeding line has servo clamping mechanism, the most front-end is

3m roller table