Add to Cart

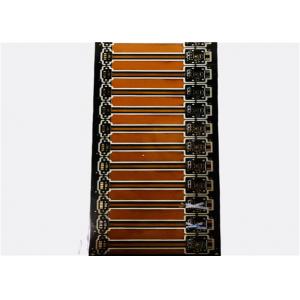

1.6mm Thickness Yellow Coverlay Rigid Flex Printed Circuit Board

(Flexible printed circuits are custom-made products, the picture and parameters shown are just for reference)

Brief Introduction of FPC

Flexible Printed Circuit Board (FPC) is referred to as "soft board". In the industry, FPC is a printed circuit board made of flexible insulating substrate (mainly polyimide or polyester film), which has many advantages that rigid printed circuit boards do not have. For example, it can be freely bent, wound, folded. The volume of electronic products can be greatly reduced by using FPC, which is suitable for the development of electronic products in the direction of high density, miniaturization and high reliability. Therefore, FPC has been widely used in aerospace, military, mobile communication, laptop, computer peripherals, PDA, digital camera and other fields or products.

FPC also has the advantages of good heat dissipation, solderability, easy mounting and low cost.

Flexible printed circuit board has one layer, two layers and multilayer board. The base material is polyimide clad laminate. This kind of material has high heat resistance and good dimensional stability. It is the final product through pressing with the coating film which has both mechanical protection and good electrical insulation. The surface and inner conductors of double-sided and multi-layer printed circuit boards are metallized to realize the electrical connection of inner and outer layers.

The function of flexible circuit board can be divided into four kinds, namely, lead line, printed circuit, connector and multifunction integrated system, which cover computer, computer peripheral auxiliary system, consumer household electrical appliance and automobile, etc.

Features and Benefits

Excellent flexibility

Reducing the volume

Weight reduction

Consistency of assembly

Increased reliability

Controllability of electrical parameter design

The end can be whole soldered

Continuity of processing

Professional and experienced engineers

High technology

Company Profile

Created in 2006,as a long history China based PCB supplier, ABIS manufactures different kinds of printed

circuit boards, including MCPCB,CEM-1,CEM-3,and FR4,FR-4 high Tg,

Rogers, Teflon, Arlon ets special material.

ABIS has set up two PCB factories in China: one for MCPCB producing, quick turn and small volumn making, and another for mass production. Currently, ABIS modern plants occupy total 10000 s.q.m facility, with more than 1100 stable and experienced workers. Professionalism and continuous optimization of manufacturing processes have positioned ABIS as a reliable and favorite partner for global companies.

PCB we can make:

1. Rigid, Flex, Rigid-Flexible PCB.

2. Buried/Blind Vias, Via in Pad, Counter Sink Hole, Screw Hole(Counterbore), Press-fit, Half Hole.

3. HASL lead-free, Immersion Gold/ Silver/Tin, OSP, Gold plating/finger, Peelable mask,

4. Printed Circuit Boards adhere to IPC Class 2 & 3 international PCB standard.

5. Quantities range from prototype to medium & big batch production.

Our Mission:

PCBs for demanding customers, on time with zero defects, produced

sustainably at the lowest total cost. Manufacturing many different

types of PCBs in smaller series (High-mix, Low-volume) involves

constantly adjusting, adapting and problem solving.

Product Details

| Number of layers | 4-16 layers |

| Technology highlights | Mixed materials including RF and high speed, standard FR-4, polyimide flex. Adhesiveless or adhesive based polyimide flex constructions, with cover coat or flexible solder mask materials. |

| Bending performance | Based on the specific design, the bend performance can range from a basic 90 °bend to fit to a full dynamic flex with 360° range of motion in the flex tail that will withstand continuous cycles throughout the product life. |

| Bend features | Bend radius controls the flexibility of the flex portion of the board. The thinner the material the lower the bend radius and the more flexible the flex section. |

| Materials | RA copper, HTE copper, FR-4, polyimide, adhesive |

| Copper weights (finished) | ½ ounce, 1 ounce, 2 ounce, 3 ounce |

| Minimum track and gap | 0.075mm / 0.075mm |

| PCB thickness | 0.4mm to 3mm |

| PCB thickness in flex section | 0.05mm to 0.8mm |

| Maxmimum dimensions | 457mm to 610mm |

| Surface finishes available | ENIG, OSP Immersion tin, Immersion silver |

| Minimum mechanical drill | 0.20mm |

Rigid PCB Capacity

| Max. No. of Layers | 20 |

| Max. Board Size | 860*610mm |

| Board Thickness | 0.2-6.0mm |

| Copper Thickness | 0.5OZ-6OZ |

| Material | Various |

| Surface Finish | Various |

| Soldermask | Various |

| Minimum Soldermask Thickness | 0.025mm |

| Minimun Soldermask BridgeDam | 0.15mm |

| Minimum Soldermask Clearance | 0.075mm |

| Peelable Colours | Blue |

| Peelable Minimum Feature | 0.5mm |

| Peelable Maximum Tented Hole | 3.0mm |

| Scoring Angle | 30 Degrees |

| Min. Remaining Thickness | 0.3mm |

| Min. Distance to copper (From center of scoring line) | 0.5mm |

| Min. Track | 0.1mm |

| Min.Gap(TrackTrack,TrackPad,PadPad) | 0.1mm |

| NPTH Min. Drill Size | 0.2mm |

| Plated Drill Size | ± 0.075mm |

| Non-Plated Drill Size | ± 0.05mm |

| Drill Location Tolerance | ± 0.05mm |

| OutlineRouted Slots | ± 0.1mm |

| Line Width/Spacing | ±10% |

| Board Thickness | ±10% |

| Warp and Twist | 0.05% |

| Scoring/V-Cut | ± 5 degrees |

| Scoring Positional Tolerance | ± 0.1mm |

| Aspect Ratio | 10:01 |

Flex PCB Capacity

| Number of layers | 1 – 6L |

| Technology highlights | Mainly polyimide materials, flex PCB’s are necessary when motion of the PCB is needed, when 3-D interconnections are necessary (i.e. replacing cables and connectors) or when these are both combined due to limited available space. |

| Materials | Polyimide, Polyester |

| Profile method | Laser cutting, punching, rout |

| Copper weights (finished) | 18μm – 70μm |

| Minimum track and gap | 0.075mm / 0.075mm |

| PCB thickness | 0.05mm – 0.80mm |

| Maxmimum dimensions | 450mm x 610mm |

| Surface finishes available | OSP, ENIG, Immersion tin, Electrolytic gold, Gold fingers |

| Minimum mechanical drill | 0.15mm |

Lead Time

| Board Type | Manufacturing Lead Time |

| Single Sided | 5 – 20 Days dependant on volume |

| PTH | 7 – 25 Days dependant on volume |

| Multilayer | 15 – 30 Days dependant on volume & Technoloy |

Certificate

FAQ

Q1:Are you a factory or trade company?

-Abis is a PCB/FPC/PCBA manufacturer/factory. We pecialize in PCB/PCBA Board for over 10 years.

Q2: How can I get a quotation:

-Please send gerber file with format: .PCB / .P-CAD / .DXP / .Gerber

Q3: Can you manufacture my PCBs from a picture file?

-Yes, we can copy for you accordingly. Could you please provide a

sample via express?

Q4: Do you have PCB in stock?

-It depends on. Most of our PCB board are customized, which according to Gerber file.

. ABIS has samples in stock that could be sent to you for quality

checking always.

Q5: Is my PCB file safe if I send it to you for manufacturing?

-We respect customer's design authority and will never manufacture

PCB for someone else without your permission. NDA is acceptable.

Q6: Will my PCB files be checked?

-Checked within 12 hours. Once Engineer's question and working file

be approved, production will start.

Q7: Can I get a sample?

- Yes, It's reasonable to get a sample to test our quality at

first.

Q8: What's your shipping way ?

-1. We have our own forwarder to ship goods by DHL, UPS, FEDEX,

TNT,EMS.

2. If you have your own forwarder, we can cooperate with them.