Natrual Gas Fusing Soda Lime 100tpd Industrial Glass Furnace

Add to Cart

Natrual Gas Fusing, Glass Melting Furnace Design And Construction

1. Brief Description

Glass is a special amorphous inorganic nonmetallic material. The main component is silicate, a non-crystalline solid with an irregular structure.

The melting process is divided into five stages as following, each section has its inner connection, affecting each other. If one stage has imperfect performance, it will influence the next stage, and ultimately affect the quality of glass.

Glass melting is the most important process in glass production, it is a forming process where the batched materials form a qualified liquid evenly with no bubbles under high temperature heating.

Technical process of glass

Capacity

| Small scale furnace | Daily furnace capacity: below 50tons |

| Medium scale furnace | Daily furnace capacity: 50tons~150tons |

| Large scale furnace | Daily furnace capacity: 150tons plus |

Product

| Flat glass furnace | For float glass, sheet glass and figured glass production line. |

| Domestic glass furnace | For container glass, tableware glass, tube glass, etc production line. |

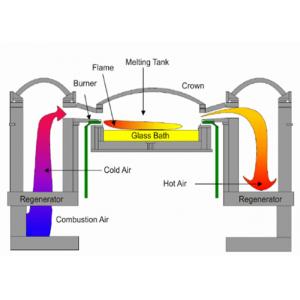

3. Furnace structure

According to current fired furnace structure, it is mainly divided into four parts:

- Glass melting section

- Heat source supply section

- Waste heat recovery section

- Gas supply and waste gas exhaust

Melting section

It is the part which melts batched materials and Clearing and homogenizes glass liquid. In the upper space of the melting section is referred to as the flame space, the lower part is melting tank.

The flame comes from the burner through the port, which feds in preheated air to increase the flame effiency.

Dog house

Batched materials feed into the furnace through dog house, the heat is transferred via flame space to the glass liquid.

Cooling section

It is a part for cooling and homogenization of the glass liquid, which is also an access for glass liquid distribution.

4. Furnace melting technology system

Reasonable melting technology is a system which could ensure a normal daily production. It will have an important function for high production, high quality, low consumption and furnace campaign.

Furnace melting technology includes temperature, pressure, bubbling, glass liquid level, fuel, reversing system etc.

Temperature

The temperature means the temperature the of melting tank, not the whole furnace. The distribution of temperature is from the melting tank through the length of the furnace.

Pressure

Furnace pressure is the static pressure of the gas system, which is determinate by pressure distribution curve.

Bubbling

Stable shape and position of bubble are an important sign to estimate the melting performance, which will also affect the production capacity of furnace and quality of glass liquid.