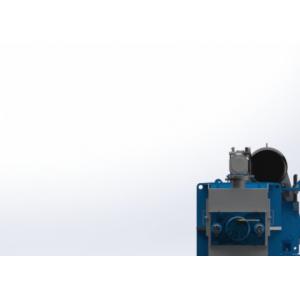

90kw Rendering Machine Press For Animals Fat And Oil

Add to Cart

Rendering Machine Fat And Oil Press

1) The function of the oil filter screen: It mainly performs simple

solid-liquid separation on the crude oil obtained by the oil press,

and the large particles of oil residue are left above the screen by

the vibration of the inclined screen surface of the filter screen

and sent to the outlet. Grease and fine oil residues pass through

the filter screen into the bottom collecting tray and are sent to

the grease pump.

2) Design overview of grease filter screen:

The separator is an inclined vibrating screen, grease and fines

hit the screen body, then, the grease can penetrate the vibrating

screen, while the solids stay on the top of the vibrating screen.

With the help of inclination and screen vibration, the solids are

sent to the outlet.

The grease that penetrates the screen is collected on the bottom

tray, and then sent to the grease pump. To ensure that the grease

level does not get too high, the grease trap should be fitted with

a grease level gauge.

The tray is equipped with an inspection and cleaning door. The

top of the separator is designed as a top cover, so that it can be

inspected and cleaned from the top. During processing, the choke

tube can be used to manually or automatically adjust the pressure

to maintain a certain pressure.

The replacement of the screen body can be realized through the top

inspection door. The separator is supplied with a set of screen

bodies with a mesh range of 0.7~1.0mm; it is supplied as a complete

set of devices, including the motor and the replaceable screen

body.

| material | carbon steel |

| power | 90kw |

| color | blue/red |