Product Details

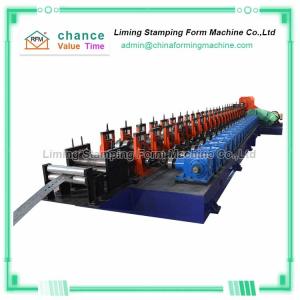

Factory direct sales customized shelf column forming machine

The shelf column forming machine is a forming equipment used to

produce shelf columns.

The forming process of the shelf column forming machine:

uncoiling-punching-feeding-roll forming-cut to length-splicing,

these processes are composed, and the shelf column forming machine

is the combination of these forming processes. A piece of

equipment, and controlled by PLC electronic control, can help you

save a lot of labor costs.

Technical parameters of Factory direct sales customized shelf column forming machine

Machine sizes: | 15*1.5*1.8m | Roller diameter: | Φ100mm |

Speed: | 8-15m/min | Power: | 45kw |

Molding row: | 12rollers | Die Material: | GCR12MOV (HCR58-62) |

Machine weight: | 35T | Transmission type: | Gearbox drive |

The punching device of the shelf column forming machine can use

roll punching. The blanking position produced by the roll punching

is accurate and the punching speed is fast, which greatly breaks

the pattern of the conventional main machine according to the

punching speed and can help you produce efficiently.

Shelf column forming machines need customized production. Because

each country has different profile sizes, mass production of shelf

column forming machines cannot be carried out. Therefore,

customized production is required, but please rest assured that we

have an experienced design team that can help you Design and

manufacture high-precision shelf column forming machines.

Company Profile

Liming Stamping Form Machine Co., Ltd. was established in 1995.

After 27 years of unremitting efforts, it has been developed from

the state-owned old factory with 8 employees to the current group

with 360 employees and the overall solution provider for industrial

chain customers with various roll forming machines.

Currently, Liming has 4 production plants and one Headquarters

R&D and Design Center. The four factories have a total area of

55,000 square meters. Liming has developed from a single roll

forming machine manufacturer into the "National Building Material

Equipment R&D Center", "Steel House Design and Installation

Company", "Metal Cold Bent Profile Entrusted Processing Company",

and has become the overall solution provider for the metal

construction industry, metal decoration industry, solar

photovoltaic industry, rolling door industry, metal fence post,

agriculture planting industry ... with 36 kinds of cold-formed

metal profiles and products.

Our designers are world-class, and go to the first-class machinery

factories in Finland, Germany and France to learn the advanced

manufacturing technology and services from European factories every

year, so as to improve ourselves and help customers to obtain

European machinery and service with minimal project investment.

It's as simple as you provide only one picture, we are capable of

making a complete set of 3D drawings, profile use scenarios,

workshop site planning and VR composition of roll forming machine.

You can 100% realize the mechanical drawings and configurations

before ordering.

It solves the problems of cheat by those companies that deceive you

with low prices and low quality, and avoids different goods ordered

and delivered. You should get the clear mechanical display for your

equipment when purchasing.

Please believe us due to our development history with constant

efforts, reject the low-quality competitive small factories and

trade companies that change industries at any time with our

technology and strength. Please give us a chance to show you every

aspect of our group.