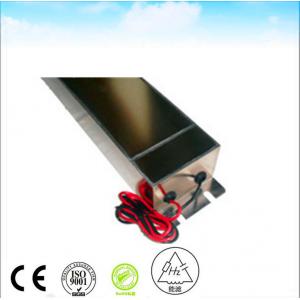

50A 120 250V Ac Dc Emi Power Line Filter Ac Noise Filter Emc Line Filter

Brand Name:nenglv

Certification:ce

Model Number:HZ-2X50C5

Minimum Order Quantity:>=1 Pieces

Place of Origin:China

Supply Ability:100 Piece/Pieces per Week

Contact Now

Add to Cart

Verified Supplier

Location:

Changzhou China

Address:

NO.5 NORTH WUQING ROAD,CHANGZHOU,JISNGSU

Supplier`s last login times:

within 37 hours

Product Details

Company Profile

Product Details

250VAC 50A Emi Power Line Filter Anechoic Chamber

| RATED VOLTAGE | 250 VAC | ||

| RATED CURRENT | 30 A | ||

| OPERATIONAL FREQUENCY | 50 60 Hz | ||

| Voltage Drop | Less than 1V | ||

| Overload | 140% of rated current for 15 minutes | ||

| Harmonic Distortion | Less than 2% @ full rated current | ||

| Leakage Current | ≤0.2A@380/230VAC and 50Hz | ||

| Dielectric Withstanding Voltage | 1000VDC (line to line) 1000VDC (line to case) | ||

| DC Insulation Resistance | As Per MIL-STD-202 Method 202 | ||

| Terminal Strength | As Per MIL-STD-202 Method 211 | ||

| Temperature Rise | As Per MIL-F-15733 | ||

| Insertion Loss | ≥100dB@14K-40GHz As Per MIL-STD-220A, Under Load Condition | ||

| Climatic Classification | 25/070/21 | ||

Filter Wiring / Connection Tips

EMI filtering works both ways. It stops noise on the power line

from getting in and stops the noise generated inside the system

from going out. Since the noise predominantly travels over the

power lines and is often radiated from those, filter

wiring/connection becomes crucial in the EMI filter installation

process. Keeping wiring best practices in mind can help to reduce a

lot of potential EMI problems.

- Aim to keep power and control wiring separated. Ensure that power and control wires do not run parallel. If cables must cross, ensure that cables cross at or as close to a right angle as possible.

- Route the conductors as close to the panel as you can.

- Ensure that the filter input and output conductors are separated.

- Keep input and output leads separated.

- Use shielded wiring if necessary, especially, on the side that needs to be protected from the radiated noise.

- Ensure that the shield of shielded cables is terminated at both ends.

- Our technical team has more than 10 years’ experience in designing EMI filter. We know UL VDE CSA CE CQC etc safety standard very well.

- Our technical service team learn many kinds of test standard such as industrial application (IEC61800-3 for frequency inverter drive EN12015 for elevator EN55011 for ISM device etc) and military application (GJB151A GJB152A etc).We can solve EMI problem quickly effectively and low-costly.

- Our test equipment: LCR digital bridge/voltage proof tester/insulation resistance tester/spectrum analyzer/inductor tester/standard signal source/shield room/interference intensity tester etc

- Our product: EMI filter for general purpose/EMI filter for frequency inverter/EMI filter for shielding facility/EMI filter for military application

- Our advantage: high quality/high cost-effective/short lead time

- Our service: all products have two years guarantee

- Our main customers: frequency inverter drive and servo drive system/MRI shielding system/solar inverter system/rail transit system etc

50A 120 250V Ac Dc Emi Power Line Filter Ac Noise Filter Emc Line Filter

Inquiry Cart

0