Add to Cart

The coating process is generally: pretreatment, polishing → coating

→ leveling → drying or curing → three wastes treatment. Coating

equipment is the mechanical equipment used to complete these

coating processes.

UV coatings are recommended for frequently handled prints such as

presentation folders, paperback book covers and certain types of

business cards. Also recommended for promotional items designed to

grab attention, such as flagship brochures and direct mail

postcards.

| 1 | It is suitable for coatings such as calcium silicate board, cement fiber board, steel plate and new building materials surface spraying real stone paint, water-in-water nano-color glaze, etc. |

| 2 | This machine adopts Japanese Mitsubishi PLC man-machine interface, Mitsubishi servo motor, inverter and other imported electrical appliances to ensure mechanical stability. |

| 3 | The spray system uses American Graco pumps and Graco large-caliber spray guns to control spray metering. |

| 4 | Slider module system: adopt Taiwan's high-speed module system with stable performance and durability. |

| 5 | The electrical part of the whole machine adopts imported electrical appliances (Schneider contactor, Mitsubishi servo, Japan Hequan switch, etc.) to ensure stable mechanical performance. |

| 6 | Effective spraying width: 1300mm. |

Conveyor system:

| 1 | he whole machine adopts acid and alkali resistant PU belt for product transportation, and the bottom is attached with paint recovery and cleaning devices to ensure that there is no residual paint on the conveyor belt, and to ensure that the back of the plate does not stick to the paint during each spraying, which effectively reduces the waste of paint. |

| 2 | Conveying speed: 1-5 m/min |

Painting system

| 1 | Adopt 4 American GRACO automatic spray guns (spray gun caliber: 1.1mm). |

| 2 | Oil supply system: Adopt Taiwan Polaroid pressure regulating and oil supply system to ensure perfect spraying quality. |

| 3 | Spray gun layout and driving mode: using two groups of spraying tracks, each group is equipped with 2 American GRACO automatic spray guns, spraying at different angles; one and two spraying tracks are controlled by OMRON infrared photoelectric induction. |

| 4 | Maximum stroke of spray gun: 3400mm reciprocating. Adjust the distance between the spray gun and the product according to the width of the product, and it is controlled by the OMRON electric eye, so that the spray gun can move in any path within the maximum stroke range, and the gun can be opened and stopped, so that the sprayed paint is uniform and can be greatly improved. Save paint, |

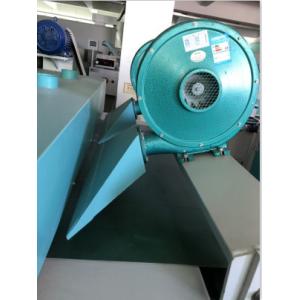

Spray booth air filtration system:

| 1 | A high-efficiency air filter is used above the automatic spraying machine to effectively filter the dust in the air and keep the spraying room clean. |

| 2 | Exhaust gas emission: adopt paper paint filter system |

Mechanical configuration:

| 1 | The front of the sprayer is equipped with a glass window for easy observation of the working condition of the sprayer. |

| 2 | Exhaust and supplementary air: Two high-efficiency fans are used to exhaust the excess waste gas during spraying to the outside (not including air ducts and ventilation facilities leading to the outside); at the same time, the intake fan makes fresh air through the filter system. To the spray booth |

| 3 | Housing material: 1.5 cold-rolled plates are bent and welded, and the housing is painted in computer color; the inner wall is made of 304# stainless steel mirror panel. |

| 4 | Electrical part: Japan OMRON relay, CKC delay, Schneider contactor, Taiwan motor Chint leakage circuit breaker and other famous-brand electrical appliances that meet international safety standards. |

| 5 | Safety devices: leakage circuit breakers, control circuit fuses, etc., and abnormal emergency switches comply with international safety standards. |

Machine control method:

| 1 | Man-machine interface: Weilun |

| 2 | . Control part: Delta PLC control |

| 3 | Sliding rail drive part: Mitsubishi servo motor. |

Warranty:

| 1 | he whole machine is guaranteed for one year and the electrical part is guaranteed for half a year. |

| 2 | The air filter is not covered by the warranty. It can be blown, wiped or cleaned directly after contamination, or it can be directly replaced with a new product |