Add to Cart

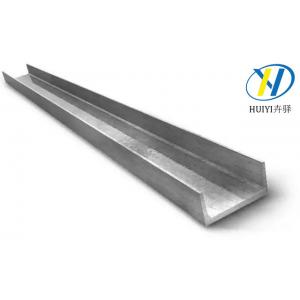

Channel steel is a kind of long steel with a groove section, which belongs to carbon structural steel for construction and machinery. Channel steel has the characteristics of complex section, mainly used in building structure, curtain wall engineering, mechanical equipment and vehicle manufacturing and other fields.

The specifications of channel steel mainly include height (h), leg width (b) and waist thickness (d), and length(L).

Such as 100*48*5.3, indicating that the waist height is 100 mm, the leg width is 48 mm, and the waist thickness is 5.3 mm, also known as 10#.

Below are some parameters table:

| Type | Size(h*b*d)(mm) | Cross-sectional area(cm2) | Theoretical weight(kg/m) |

5# | 50*37*4.5 | 6.928 | 5.438 |

| 8# | 80*43*5.0 | 10.248 | 8.045 |

| 10# | 100*48*5.3 | 12.748 | 10.007 |

| 12# | 120*53*5.5 | / | 12.059 |

Below are some actual shipment parameters table:

| Size(h*b*d*L)(mm) | Weight(kg/m) | Weight(kg/piece) |

| 75*40*5*6 | 6.920 | 41.520 |

| 100*50*5*6 | 10.600 | 63.600 |

The production process of channel steel includes the following steps:

1. Raw material preparation: The main raw material of channel steel is billet, which is obtained through the smelting process of steel mills. Before the production of channel steel, the quality inspection of the billet is required to ensure that it meets the relevant standards.

2. Billet heating: the billet that has passed the quality inspection needs to be heated. The purpose of heating is to make the billet reach a certain temperature so that the subsequent rolling process can proceed smoothly. Heating is usually carried out in a high temperature furnace, and the temperature control should be precise.

3. Rolling: The heated billet enters the rolling mill for rolling. Rolling is the plastic deformation of the billet through a series of rollers to form the desired shape of the channel steel. It is necessary to control the rolling force and the rolling temperature in the rolling process to ensure that the dimensions and properties of the channel steel meet the requirements.

4. Cooling: The rolled channel steel needs to be cooled. The purpose of cooling is to rapidly reduce the temperature of the channel steel, fix its internal structure, and improve its strength and hardness. Cooling is usually carried out by water cooling or air cooling.

5. Surface treatment: The surface of the channel steel may need to be treated to improve its corrosion resistance and aesthetics. Common surface treatment methods include hot dip galvanizing, spray painting and so on.

Channel steel is a common steel profile with the following characteristics:

1. Material: Channel steel is usually hot-dip galvanized carbon

structural steel, such as the steel specified in ASTM A36 standard.

2. Galvanizing treatment: Channel steel after hot dip galvanizing

treatment, can improve its corrosion resistance, extend the service

life.

3. Good mechanical properties: channel steel has high tensile

strength, yield point and elongation and other mechanical

properties, can withstand large loads and stresses.

4. Lightweight design: Channel steel is also divided into ordinary

channel steel and light channel steel two types. Light channel

steel is thinner than ordinary channel steel waist thickness and

leg thickness, and the unit weight is lighter, which is suitable

for bearing small loads.

5. Adjustable size: The size of the channel steel can be adjusted

according to needs to meet different engineering requirements.

Channel steel is a commonly used steel, with a wide range of applications, such as building structures, curtain wall engineering, mechanical equipment and vehicle manufacturing. It has a variety of specifications and can be selected according to the specific needs of the appropriate specifications and models.

Packing: Four packing belts on each bundle, weight under 3mt for per bundle.

We will always adhere to the principle of "quality first,service supreme,mutual benefit". HUIYI will create brilliant future together with you.

FAQ

The following are frequently asked questions (FAQ) about channel steel and related precautions:

1.Q: What are the uses of channel steel?

Channel steel is mainly used in building structure, curtain wall engineering, mechanical equipment and vehicle manufacturing and other fields.

2.Q: What are the specifications of channel steel?

The specifications of the channel steel are usually expressed by the model, such as 5#, 6.3#, 8#, etc., and different specifications of the channel steel have different sizes and cross-section shapes.

3.Q: What is the material of channel steel?

Channel steel is usually made of carbon structural steel, such as ordinary carbon structural steel, low alloy high strength steel, etc

4.Q: How to choose the right channel steel?

The selection of suitable channel steel needs to consider the specific use requirements and application scenarios. You can choose according to the required size, material, strength and other requirements, and fully communicate and understand with the supplier to ensure that the purchased channel steel can meet the needs.

1. Storage precautions for channel steel:

When the channel steel is stacked in the open air, the wooden pad or strip stone should be used under the pile surface, and the pile surface should be slightly inclined to facilitate drainage. At the same time, pay attention to place the channel steel flat and straight to prevent bending and deformation. Stacking height should be controlled according to manual and mechanical operation requirements to ensure safety.

2. Precautions for processing channel steel:

During the processing of channel steel, it is necessary to pay attention to safe operation, select the appropriate processing equipment and tools, understand the material characteristics, adjust the processing parameters, use the appropriate cutting lubricant, and carry out regular inspection and maintenance. By following these considerations, the quality and efficiency of channel processing can be improved while ensuring operator safety.