Add to Cart

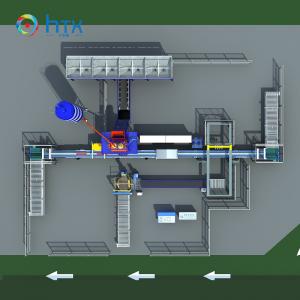

A wet concrete Fence Panel production line is a set of equipment and processes used to produce

wet concrete continuously and efficiently. Wet concrete Fence Panel production lines are commonly used in the construction industry to

produce large amounts of concrete for various construction

projects.

The wet Fence Panel concrete production line typically includes several pieces of

equipment, such as a concrete mixer, a batching plant, a conveyor

system, and a set of molds. The concrete mixer is used to mix the

concrete ingredients, while the batching plant is used to weigh and

mix the ingredients in the correct proportions. The conveyor system

is used to transport the wet concrete from the mixer to the molds,

where it is shaped into the desired form.

The wet concrete Fence Panel production line can be configured in different ways depending on

the specific requirements of the project. For example, a production

line can be designed to produce a specific type of concrete mix,

such as high-strength concrete, or it can be designed to produce a

variety of different mixes. The production line can also be

designed to produce concrete products of different sizes and

shapes, such as concrete blocks, pavers, or precast panels.

One of the main advantages of a wet concrete production line is the

ability to produce large amounts of concrete continuously. This can

help to improve the efficiency of the production process and reduce

labor costs. Additionally, the use of automated equipment and

processes can help to improve the consistency and quality of the

concrete mix.

Overall, a wet concrete production line is a valuable asset for

construction companies that require a continuous supply of

high-quality concrete for their projects. By investing in a wet

concrete production line, companies can increase their production

capacity, improve efficiency, and reduce costs.

Specification:

| Name | Model | Specification | Size(mm) | Power(Kw) | Capacity(m2/day) | Weight(Kg) |

| Wet Cast Machinery | HTX-P-01 | Hydraulic driving;Auto feeding; vibrating and timing feeding | 7000*1000*1800 | 12.7 | 1000-1500 | 2000 |

| Wet Cast Machinery | HTX-P-02 | Chain drived;Auto feeding,auto vibration | 8000*1100*1600 | 4.05 | 800-1000 | 1500 |

Applications

Wet cast machinery, is suitable for different silicone molds,

rubber molds and plastic molds, size range from 200*200mm to

1500*1500mm, available for producing the artificial stone both for

paving tile molds, 3D wall molds, wall panel molds, roadside stone

molds, retaining wall molds, wall cap molds, etc.

Support and Services

Wet Cast Machinery technical support and services include: