Add to Cart

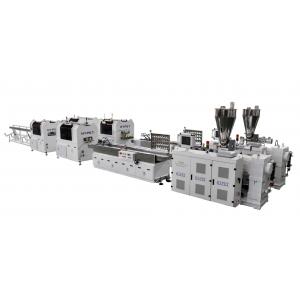

Production Line Brief introduction:

| Features | High output | 180-320kg/h for different type |

| High efficient | Stable quality, efficient operation make high qualified | |

| Energy saving | It can save energy 20-30% by machine and software. | |

| Intelligent AI control | PLC + HYPET software to control the operation automatically and save each formulation case. | |

| Machine information | Popular types for using | Single head , double head, and four head type |

| Product shape and size | Can be done as the customer required. | |

| Caco3 amount | From 30phr to 100 phr when PVC 100 phr. | |

| Mould material | 4Cr13 with heat treatment HB280-310 | |

| Calibrating mould legnth | 200mm | |

| Water Cooling tank length | 1200mm shear with each other | |

| Working condition | Electric power | 3-phase, 380v +/- 10% , 50Hz (others for option |

| Total power | Depends different lines | |

| Cooling water | ≤ 20°C ≥ 0.3Mpa | |

| Compressed water | > 0.3m3/min, > 0.5Mpa | |

| Overall sizes ( L*W*H) | 22000* 1600*2500 mm |

HYZS65/132 conic twin screw extruder with HYYF240 cable duct down stream line:

| SN | Parts name | Qty |

| 1 | HYZS65/132 conic twin screw extruder with 37kw motor | 1 |

| 2 | Calibrating table in 4 m Vacuum pump 5.5kw*1 Water pump 1.5kw*1 | 1 |

| 3 | Haul off unit two claws type, 1.5kw*2 sets | 1 |

| 4 | Cutter in 2.2kw cutter sizes Max 240*70mm | 1 |

| 5 | Stacker | 1 |

| 6 | Punching device possible for option |

Cable duct mould list:

| SN | Mould Name | Qty |

| Mould in single head material 4Cr13 stainless steel | ||

| 1 | 40*30 in single head ( one bottom+ one cover ) | 1 |

| 2 | 50*25 in single head ( one bottom+ one cover ) | 1 |

| 3 | 60*40 in single head ( one bottom+ one cover ) | 1 |

| 4 | 60*60 in single head ( one bottom+ one cover ) | 1 |

| 5 | 80*60 in single head ( one bottom+ one cover ) | 1 |

| 6 | 100*40 in single head ( one bottom+ one cover ) | 1 |

| 7 | 100*60 in single head ( one bottom+ one cover ) | 1 |

| 8 | 100*100 in single head ( one bottom+ one cover ) | 1 |

| 9 | 120*80 in single head ( one bottom+ one cover ) | 1 |

| 10 | 150*50 in single head ( one bottom+ one cover ) | 1 |

| 11 | 150*100 in single head ( one bottom+ one cover ) | 1 |

| 12 | 200*100 in single head ( one bottom+ one cover ) special sizes | 1 |

| 13 | 200*150 in single head ( one bottom+ one cover ) special sizes | 1 |

Technical specification:

| SN | Items | Description |

| HYZS65/132 conic twin screw extruder | ||

| 1 | Extruder model | HYZS-65/132 conic twin screw |

| 2 | Output | 280-320 for profile |

| 3 | Screw diameter | Ø65/132 mm |

| 4 | Screw material | 38CrMoAlA + special alloy |

| 5 | Heat treatment | Nitrogen-filled (0.50~0.70mm depth) |

| 6 | Core of the screw | Auto control for temperature (Oil cooling will be for option ) |

| 7 | Rotate speed | 0~38 r/min |

| 8 | Barrel Structure | Bimetallic In two parts, front part will be with special alloy inserted. |

| 9 | Front part of the barrel | SKD11 with heat treatment |

| 10 | Inside finish | Nitrogen-filled (0.50~0.70mm depth) |

| 11 | Heating control area | 4 zones |

| 12 | Heating way | Cast aluminum/ ceramics |

| 13 | Heating power | 22 kW |

| 14 | Cooling system | Low-noisy barrel cooling fan |

| 15 | Cooling power | 0.2kwx2 sets +0.3kW x 1 set |

| 16 | Temp & pressure Transducer | China famous brand with isolated cable. |

| 17 | Gear box brand | HYMAX gear box made by HYPET |

| 18 | Housing material | Ductile iron |

| 19 | Gear material | 20CrMnTiA |

| 20 | Gear surface | Hardened and ground in high precision |

| 21 | Axis material | 40Cr |

| 22 | Temperature of oil | Controlled by two system |

| 23 | Rubber sealer | Imported special rubber sealer used |

| 24 | Bearings | With famous and reliable brand. |

| 25 | Dosing feeder | Twin screw feeding type |

| 26 | Motor power | 1.1kw |

| 27 | Speed range | 1-50 RPM |

| 28 | Powder bridge | Anti powder bridge with high Caco3 |

| 29 | Control | heavy loader type inverter |

| 30 | Vacuum degas motor power | 2.2 kw |

| 31 | Vacuum degree | -0.04Mpa |

| 32 | Vacuum tank | Easy to be clean |

| 33 | Driving motor | AC Motor heavy type famous brand |

| 34 | Motor power | 37kw |

| 35 | AC inverter controller | Famous Delta in heavy type |

| 36 | Electrical Control system | Siemens PLC+ HYPET AI auto control system |

| 37 | Electric components | Branded in Siemens, Schneider Omron, Delta /ABB, FUJI, and small unimportant parts in China famous brand |

| 38 | Extra temperature zone for die | 8 zones |

| 39 | display screen size | 14” big size monitor |

| 40 | Electric cabinet cable | Easy to be disassemble by joints |

| 41 | Extra power adaptor | For down stream, and other machine |

| Cable duct down stream machines | ||

| Calibrating table | ||

| 1 | Material | Stainless steel S304 for watering material |

| 2 | Length | 4,000mm |

| 3 | Center height | 1,000 mm |

| 4 | Max. product width | 240mm |

| 5 | Mold assembling size | 320mm |

| 6 | Vacuum pump | 5.5 kW x 1 set |

| 7 | Water pump | 1.5 kW x 1 set |

| 8 | Hot dryer pump | 1.5kW*2 |

| 9 | Vacuum joints | 20 pcs |

| 10 | Water pipe joints | 20 pcs |

| 11 | Center height | 1,000mm +/- 50mm adjustable |

| 12 | Water gas separator | For multi pumps (3) |

| 13 | Vacuum connection | Ø50mm *2 |

| 14 | Water connection | Ø50mm *2 |

| 15 | Movable motor power | 0.75 kW |

| 16 | Moving range of front & rear | 800 mm |

| 17 | Vertical moving range | 850~960mm |

| 18 | Tilt adjustment | 1-25mm by manual |

| 19 | Cross adjustment | 1-50mm |

| 20 | Left and right adjustment | 1-120 mm |

| Haul off | ||

| 1 | Haul off type | Up-down 2 claw type |

| 2 | Max. Product size | 240mm width x 70mm thickness |

| 3 | Rubber block width | 240mm |

| 4 | Haul off force | 30,000 N |

| 5 | Max. speed | 0.5~7m/min |

| 6 | Haul off shape | Can suitable for different product shape |

| 7 | Effective Length of caterpillar | 2,000mm |

| 8 | Motor | AC motor, with famous inverter |

| 9 | Power | 1.5 kW x 2 sets |

| 10 | Clamp and adjustment type | 2 individual cylinder |

| 11 | Center height | 1,000mm |

| Cutter | ||

| 1 | Cutting type | Saw cutter |

| 2 | Max. Cutting size | 240mm width x 100mm thickness |

| 3 | Cutting movement | Transverse movement |

| 4 | Follow up by | Clamping duct in runing |

| 5 | Cutting Motor power | 2.2 kW |

| 6 | Dust-absorb device | 2.2 kW x 1 set |

| 7 | Air pressure | 0.5~0.7Mpa |

| 8 | Moving method | Pneumatic |

| 9 | Control method | PLC control |

| Stacker | ||

| 1 | Tilting table | Pneumatically operated |

| 2 | Nominal length | 4~6m |

| 3 | Material of tripping chute | MS rigid structural steel |

| 4 | Control method | PLC control |