Add to Cart

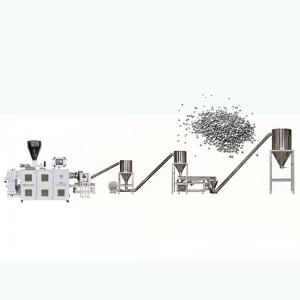

Plastic Pelletizing Line / Pvc Granules Making Machine 200-1000kg/h

Plastic Pelletizing Line / Pvc Granules Making Machine Main machines

Plastic Pelletizing Line / Pvc Granules Making Machine HYPET unique advantages of parallel twin screw extruder

Except the same features with other supplier.

Plastic Pelletizing Line / Pvc Granules Making Machine Configuration list

Note: This table as attached file which is for selection of the configuration on the whole line

| SN | Items | Choosing configuration | Other option |

| 1 | Production control system | PLC is for option | Digital control system |

| 2 | Cooling system of the main control electric cabinet | Fan cooling | Air conditioner for option |

| 3 | Main motor | AC motor with famous inverter | DC is for option |

| 4 | Pressure sensor | HYPET individual temperature and pressure control in two parts | Dynisco is for option |

| 5 | Core thermoregulation control | internal closed loop heat balancing system. | External heat control option |

| 6 | Material of screw & barrel | 38CrMoAlA+Special alloy+polishing | Standard nitro with alloy plating option |

| 7 | Quantitative feeding system’s mixing function | Twin screw with mixing device option | Dosing device in single screw type. |

Plastic Pelletizing Line / Pvc Granules Making Machine Condition of use

1. Plastic Pelletizing Line / Pvc Granules Making Machine Technical features of whole line

| SN | Specification | Description | Remark |

| 1 | Suitable material | PVC powder | |

| 2 | Max. output | 200~1000kg/h | |

| 3 | Test and accept | Based on HYPET standard formula. | |

| 4 | Air cooling system | 2 or 3 sets | |

| 5 | Center height | 1000mm-1100mm | |

| 6 | Whole line size (L x W x H) | 9000 x 1240 x 2520mm | |

| 7 | Operation direction | From right to left | |

| 8 | Color of equipment | HYPET white color | |

| 9 | Control of whole production | Refer to the “configuration list”. | |

| Note | Extrusion capacity will be changed according the processing material and working conditions | ||

2. Plastic Pelletizing Line / Pvc Granules Making Machine Circumstances condition

| SN | Condition | Specification | Description |

| 1 | Natural circumstance condition | Working place | Indoor use |

| Humidity | 85% no condensation | ||

| Temperature | 0~40 ℃ | ||

| 2 | Electricity source | Installation capacity | 80kw-500kw |

| Power supply | 3P+N+PE | ||

| Voltage/Frequency | 380V/50Hz other can be option | ||

| 3 | Cooling water | Temperature | ≤15 ℃ |

| Water pressure | ≥0.3MPa | ||

| Flow | ~15 m3/h | ||

| 4 | Air condition | Compressor air pressure | ≥0.6MPa |

| Flow | ~0.9 m3/min |

Plastic Pelletizing Line / Pvc Granules Making Machine

Plastic Pelletizing Line / Pvc Granules Making Machine Terms of payment

1) T/T and L/C (irrevocable, at sight) both are acceptable.

2) 35% of the total contract value should be paid in advance, balance 65% of the total value is to be paid before shipping at the Seller’s factory.

Plastic Pelletizing Line / Pvc Granules Making Machine Time of delivery

1) When the contract becomes valid, the machine should be delivered within 60 days since receipt of the advance payment. And the equipment will be in normal operation after debugging within two weeks after arrival.

2) During production, provided that the Buyer requests to modify the specification of the order, the Buyer shall notify the Seller of this modification in written form. Upon receipt of the notice, the Seller will quote to the Buyer the cost of this modification and notify the Buyer of any possible delay due to this modification.