Add to Cart

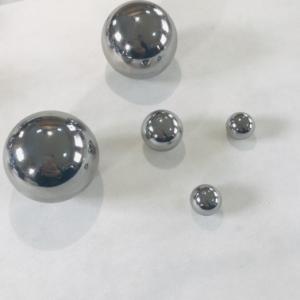

44.45mm(1-3/4"), Large Solid Stainless Steel Metal Ball For Bearing

Introduction

Stainless steel balls are usually produced through a stainless steel forging process. At present, the commonly used stainless steel balls are 201, 302, 304, 316, 316L, 420, 440C.

According to the organization state, stainless steel is usually

divided into martensitic steel, ferritic steel, austenitic steel,

austenitic-ferritic (duplex) stainless steel and precipitation

hardening stainless steel. In addition, according to the

composition can be divided into: chromium stainless steel, chromium

nickel stainless steel and chromium manganese nitrogen stainless

steel and so on.

304 is a versatile stainless steel, which is widely used to make

equipment and parts that require good overall performance

(corrosion resistance and formability). In order to maintain the

inherent corrosion resistance of stainless steel, steel must

contain more than 18% chromium and more than 8% nickel.

Industry Standard Grade10 420 Stainless Ball Bearings: High Quality

Graded 420 Stainless Steel Ball bearings made from AISI 420

Stainless Steel with a hardness of 52 -55 HRC Rockwell Scale, the

hardness is all the way through the ball. These are the same

stainless 420 steel balls used to manufacture bearing assemblies

and have a high duty and life cycle.

The most commonly used martensitic stainless steel giving fair

corrosion resistance to fresh water, steam, petrol, alcohol, oils

and foodstuffs.

Manufactured in compliance to the following international

standards: AISI 420 / BS970 420S37 420S45 / DIN 1.4021, 1.4025,

1.4034 / AFNOR Z30C13, Z40C14 / JIS SUS 4200JI, 420J2.

Note: Ferritic stainless steel cannot maintain its strength at high

temperatures, so it is not used when strength is needed.

The relationship between the main chemical composition and the

performance of stainless steel.

1. Carbon will increase hardness and strength, high content will

reduce its ductility and corrosion resistance

2. Chromium can increase corrosion resistance, oxidation

resistance, refine grain, increase strength, hardness and wear

resistance

3. Nickel can improve high temperature strength, corrosion

resistance, and reduce cold work hardening rate

4. Molybdenum improves strength and has excellent corrosion

resistance to oxides and seawater

5. Copper is good for cold forming and reduces magnetic properties

6. Mn is mainly used to reduce the magnetic properties of the

material, but the content should not be too high.

| Product name | forged solid stainless steel ball for bearing |

| Meterial | 304 316 420 440 stainless steel ball for bearing |

| Size | Ф0.3 – Ф100mm |

| Other size | Customized |

| Surface treatment | Mirror polished, smooth |

| Application | Medical equipment, chemical industry, aviation, aerospace, plastic hardware: perfume bottle, sprayer, valve, nail polish, Motor, switch, electric iron, washing machine, refrigerator, air conditioner, medicine, auto parts, bearing, instrument, milk bottle. |

1. Q: Can you provide free sample?

Yes, we can offer you free sample when we have them in stock.

2. Q: What is the lead time?

Balls in stock could be delivered within 3-5 days once confirmed

the order.

For mass order or customized products, it takes about 20-30 days

3. Q: What's your advantage? Why we choose you?

1) More than 20 years balls manufacture experience.

2) Great production capacity Sustainable Supply. According to

customer requirements. We support the customized products including

package.

3) Large stock and wide size range.