Add to Cart

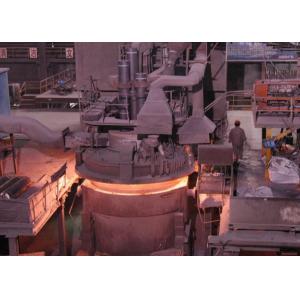

LF series LF-120t ladle refining furnace

Ladle Refining Furnaces are used to raise the temperature and adjust the chemical composition of molten metal. Without LRFs, higher tap temperatures are normally required from steel making furnaces due to heat losses during refining with conventional ladles.

Molten Metal Ladle Refining Furnace include Furnace body; IF power supply units; Reducer or Hydraulic station; Crucible; Water Cooled Cable.

Furnace body uses aluminium alloy material,steel shell type covered magnetic plates, power supply with KGPS standard.

Parameter

| No. | Product name | Unit | Data | Remarks |

| 1 | Block of LF furnace | seat | 1 | |

| 2 | To deal with every steel water | 1 | 60 | 70 max. |

| 3 | LF furnace transformer rated capacity | MVA | 1.2 | 20% overload |

| 4 | Primary voltage | KV | 35 | |

| 5 | Secondary voltage | V | 270-250-170 | No-loading adjust voltage 6 grade |

| 6 | Secondary current | A | 27700 | |

| 7 | Heating rate | ℃/min | 4.0 | Max. 6.0 |

| 8 | Electrode diameter | mm | 400 | UHP |

| 9 | Average refining cycle | min | 35 | |

| 10 | Electrode moving distance | mm | 2500 | |

| 11 | Electrode moving speed | M/min | 3-4 | |

| 12 | Refining ladle car load | T | 150 | |

| 13 | Refining ladle car speed | M/min | 12 | |

| 14 | Furnace hearth diameter | mm | ∅2500 | 60t molten steel surface |

| 15 | Ladle upper diameter | mm | ∅3000 | |

| 16 | Ladle height | mm | 3700 | |

| 17 | Free space height | mm | 450 | 60t molten steel surface |

| 18 | Cooling water inlet | ℃ | ≤34 | |

| 19 | Temperature rise | ℃ | ≤15 | |

| 20 | Cooling water flow | M3/h | 200 | |

| 21 | Water pressure | MPa | ≥0.35 | |

| 22 | Power supply | V | 35000(380-220) | High voltage(IOW) |

| 23 | Frequency | Hz | 50 | |

| 24 | Compressed air | Mpa | ≥0.4 | No water no oil |

Function

1. Electric arc heats up and temperature rises under constant pressure, measure temperature and take samples, finally temperature control is accurate so as to optimize casting temperature.

2. Synthetic slag goes through refining, desulfuration, deoxidation, degasification and removal of inclusions

3. Bottom blowing argon siring. make liquid steel temperature uniform and make components uniform and pure.

4. Alloy fine adjustment makes component controlled accurately. The finally required chemical composition could be achieved with high efficiency through ferroalloy element or aluminum or wire feeding.

5. Being equipped with wire feeder makes liquid steel realize desulfuration and deoxygenation, changes inclusion pattern and distribution and accurately controls alloy elements. And it has high alloy yield, low temperature drop and low environmental pollution.

6. As buffering equipments between primary melting furnace and continuous casting machine, ensure matching production of primary meting furnace and continuous casting, realize sequence casting.

Characteristics

1. Adopting the water cooled furnace roof equipped with dedusting interface of which the size of smoke outlet is adjustable to keep the tiny barotropic atmosphere and reducing atmosphere inside the furnace.

2. Using the cooper-steel composited conductive arm, reducing electrode pitch circle diameter and prolonging lining service life.

3. Equipped with automatic or manual temperature measurement and sampling device to measure the liquid steel temperature accurately.

4. Large current system adopts large-section water cooled cable, compensators and copper-steel composite conducive arm, thus reduce major loop impedance.

5. Using alloy and slag automatic charging device to accurately measure the charging volume.

6. Equipped with PLC control system and smelting model.

Selling Units: Single item

Single package size: 150*100*170cm

Single gross weight: 100,000kg

Package Type: Safety Seaworthy Package

Lead Time:

| Quantity (Tons) | 1-100 | >100 |

| Est. Time(Days) | 60 | To be negotiated |