Add to Cart

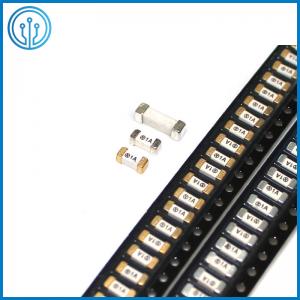

Non-Resettable Quick Blow Surface Mount Ceramic Fuse 1032 1A 2A 3.15A 350V 400V DC

Description Of The Non-Resettable Quick Blow Surface Mount Ceramic Fuse 1032

Non-resettable surface mount fuses are single-use circuit protection devices that break a circuit when a fault is detected. This type of fuse is designed to be mounted directly onto a printed circuit board (PCB).

Non-resettable surface mount fuses offer circuit protection by

breaking the circuit when detecting a fault. They are designed to

be mounted directly onto a printed circuit board (PCB) and are

available with a range of voltages, current ranges and resistance

levels. They work by melting the metal strip inside the fuse during

and overcurrent or short circuit event, which means they must be

replaced once the fuse has blown.

We supply a variety of non-resettable surface mount fuses suitable

for a range of applications, from manufacturers including one time

fuse and resettable fuse.

Features Of The Non-Resettable Quick Blow Surface Mount Ceramic Fuse 1032

► Fast-acting high current fuse

► Compact design utilizes less board space

► 1 A to 3.15A current ratings

► Ceramic tube, silver plated brass end cap construction

► DC 350V 400V

Application Of The Non-Resettable Quick Blow Surface Mount Ceramic Fuse 1032

► LED Driver

► Industrial application

► Telecom Devices

► Server and desktop power supplies

► Gaming console systems

► Voltage Regulator Module (VRM)

► Storage system power

► Base station power supplies

► Basic power supplies

► LED and general lighting

► Test equipment

Specification Of The Non-Resettable Quick Blow Surface Mount Ceramic Fuse 1032

| Attribute | Value |

| Current Rating | 1-3.15A |

| Fuse Size | 3 x 10 mm |

| Fuse Speed | F |

| Voltage Rating | 350V 400V DC |

| Body Material | Ceramic |

| Series | 1032F |

Ordering Info Of The Non-Resettable Quick Blow Surface Mount Ceramic Fuse 1032

Catalog No. | Ampere Rating | Voltage Rating | Breaking Capacity | Nominal Cold Resistance (Ohms) | I2TMelting Integral(A2.S) | Agency Approvals | |

| UL | cUL | ||||||

| R1032F.1100 | 1A | 350V/400V DC | 100A@350V/400V 50A@400V350V | 0.177 | 3.912 | ● | ● |

| R1032F.1125 | 1.25A | 0.122 | 7.040 | ● | ● | ||

| R1032F.1150 | 1.5A | 0.072 | 11.22 | ● | ● | ||

| R1032F.1160 | 1.6A | 0.071 | 12.53 | ● | ● | ||

| R1032F.1200 | 2A | 0.055 | 14.20 | ● | ● | ||

| R1032F.1250 | 2.5A | 0.041 | 28.02 | ● | ● | ||

| R1032F.1300 | 3A | 0.032 | 44.50 | ● | ● | ||

| R1032F.1315 | 3.15A | 0.031 | 45.20 | ● | ● | ||

Breaking Capacity: 50A@350V400Vdc,100A@350V400Vdc.

Operating Characteristics

% of Ampere Rating(In) | Blowing Time |

| 100% * In | 4 hours Min |

| 200% * In | 120 sec Max |

Choosing between a PTC and a Fuse

Overcurrent circuit protection can be accomplished with the use of

either a traditional fuse or the more recently developed resettable

PTC. Both devices function by reacting to the heat generated by the

excessive current flow in the circuit. The fuse melts open,

interrupting the current flow, and the PTC changes from a low

resistance to a high resistance to limit current flow.

Understanding the differences in performance between the two types

of devices will make the best circuit protection choice easier.

The most obvious difference is that the PTC is resettable. The

general procedure for resetting after an overload has occurred is

to remove power and allow the device to cool down. There are

several other operating characteristics that differentiate the two

types of products. The terminology used for PTCs is often similar

but not the same as for fuses. Two parameters that fall into this

category are leakage current and interrupting rating.

Leakage current: the PTC is said to have “tripped” when it has

transitioned from the low resistance state to the high resistance

state due to the overload. Protection is accomplished by limiting

the current flow to some leakage level. Leakage current can range

from around a hundred milliamps at rated voltage up to several

hundred milliamps at lower voltages. The fuse on the other hand

completely interrupts the current flow and this open circuit

results in “0” leakage current when subjected to the overload.

Interrupting rating: the PTC is rated for a maximum short circuit

current at rated voltage. This fault current level is the maximum

current that the device can withstand but the PTC will not actually

interrupt the current flow (see LEAKAGE CURRENT above). A typical

PTC short circuit rating is 40A. Fuses do in fact interrupt the

current flow in response to the overload and the range of

interrupting ratings goes from hundreds of amperes up to 10,000

amperes at rated voltage.

The circuit parameters may dictate the component choice based on

typical device rating differences.

Voltage rating: general use PTCs are not rated above 60V while

fuses are rated up to 600V. Current rating: the operating current

rating for PTCs can be up to 11A while the maximum level for fuses

can exceed 20A.

Temperature rating: the useful upper limit for a PTC is generally

85° while the maximum operating temperature for fuses is 125°C.

Both devices require derating for temperatures above 20°C and a

representative curve for that purpose is provided.

The PTC Rerating Curves located on data pages, should be consulted

for the proper rerating of the various PTC series at ambient

temperatures other than 20°C.

Additional operating characteristics can be reviewed by the circuit

designer in making the decision to choose a PTC or a fuse for

overcurrent protection.

Agency approvals: PTCs are recognized under the Component Program

of Underwriters Laboratories to UL Thermistor Standard 1434. The

devices have also been certified under the CSA Component Acceptance

Program. PTCs can, in addition, be approved to IECStandard 730-1

(Automatic Electric Controls) with certification by TUV, VDE, etc.

Approvals for fuses include recognition under the Component Program

of Underwriters Laboratories and certification from the CSA

Component Acceptance Program. In addition many fuses are available

with full “Listing” in accordance with the new Supplementary Fuse

Standard UL 248-14.

Resistance: Reviewing product specifications indicates that

similarly rated PTCs have about twice (sometimes more) the

resistance of fuses. Time-current characteristic: comparing the

time-current curves of PTCs to fuses shows that the speed of

response for a PTC is similar to the time delay of a Slo-Blow fuse.