Add to Cart

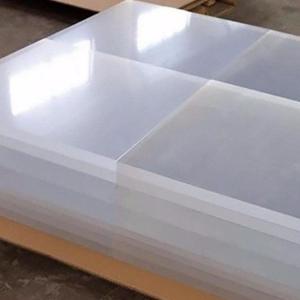

"The Belt and Road" special product PMMA Transparent Plate

Production Line PMMA Plate Extrusion Machine :)

PMMA Acrylic Plate Industry: Opportunities in Belt and Road Countries

This article analyzes the relationship between the PMMA acrylic

sheet industry and the Belt and Road countries, exploring the

cooperation opportunities and prospects brought by the Belt and

Road Initiative. With the rapid economic development and

strengthened infrastructure construction in the Belt and Road

countries, the PMMA acrylic sheet industry has gradually become a

beneficiary, achieving significant progress in cooperation.

Introduction:

The PMMA acrylic sheet industry, which emerged in the mid-20th

century, has a wide range of applications in fields such as

construction, furniture, lighting, and advertising. In recent

years, with the advancement of the Belt and Road Initiative, the

PMMA acrylic sheet industry has started deepening cooperation with

Belt and Road countries, gaining more opportunities and

development.

Firstly, as one of the regions with the greatest development

potential and infrastructure construction demand globally, the Belt

and Road countries provide enormous market demand for the PMMA

acrylic sheet industry. The rapid economic development and

accelerated urbanization processes in these countries have led to

an increasing demand for high-quality acrylic sheets. As a material

with excellent performance, high transparency, and weather

resistance, PMMA acrylic sheets are widely sought after in various

indoor and outdoor applications, such as architectural facades,

outdoor billboards, and interior furniture. The market potential of

the Belt and Road countries offers long-term and stable development

prospects for the PMMA acrylic sheet industry.

Moreover, the infrastructure construction in Belt and Road

countries presents new opportunities for cooperation in the PMMA

acrylic sheet industry. As a part of infrastructure development,

many transportation, energy, and construction projects in Belt and

Road countries require a significant amount of acrylic sheets. For

example, acrylic soundproof panels and shielding screens become

essential materials in highway, railway, and airport infrastructure

projects. Additionally, some energy projects demand acrylic sheets,

such as acrylic protective layers on solar photovoltaic panels. The

infrastructure construction in Belt and Road countries provides

ample space for cooperation in the acrylic sheet industry.

Lastly, the advancement of the Belt and Road Initiative accelerates

technological exchanges and collaboration among PMMA acrylic sheet

industry players. Companies from different countries participate

jointly in Belt and Road projects, collaborating in areas such as

technology research and development, production processes, and

market expansion. This cross-border cooperation enables the PMMA

acrylic sheet industry to leverage various strengths, improve

competitiveness, and provide more choices and technical support to

Belt and Road countries.

Conclusion:

In conclusion, the PMMA acrylic sheet industry has developed a

close relationship with the Belt and Road countries, benefiting

from the increasing market demand, infrastructure construction

opportunities, and technological exchanges. With the further

advancement of the Belt and Road Initiative, the PMMA acrylic sheet

industry is expected to seize more cooperation opportunities in

terms of market demand, infrastructure construction, technological

innovation, and market expansion. This cooperation will drive the

development of the PMMA acrylic sheet industry and provide

significant support to the economic construction and social

progress in Belt and Road countries.

PP PE sheet is widely as envinromentally friendly product which is

widely applied in chemical industry,food industry,anti-corrosion

industry,home appliance,electronics and packaging as well as other

related industries.

PP PE ABS PMMP PC sheet sizes:

Width:1200-3600mm;

Thickness:3-40mm;

Length:customzied.

PP PE PMMA PC PS ABS Sheet Making Machine Description:

1. Special screw design could efficiently increase the

plasticization and output up to 800kg/h.

2. Optimized electrical design could achieve automatic control on

adjustment and control precisely.

3. Production line adopts Siemens motor,ABB inverter,Schneider

contactor and Siemens PLC control system and Siemens touch

screen.Reliable electrical components and special designed program

could guarantee the machine running smoothly,save power and reduce

the waste.

Specification of PMMA Transparent Plate Production Line:

| Type | GWS90-800 | GWS120-1000 | GWS150-1500 |

| Raw materials | PMMA | ||

| Product width | 600mm | 800mm | 1220mm |

| Product thickness | 0.5-5mm | 0.5-5mm | 0.5-5mm |

| Extruder type | Single screw GWS90/35 | Single screw GWS120/35 | Single screw GWS150/35 |

| Design output | 200Kg/h | 350Kg/h | 450kg/h |