Add to Cart

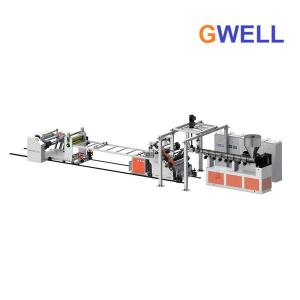

PP Sheet Thermoforming Extrusion machine Used For Disposable Food Packing Container Long Life And High Output

1. Features of PP/PS sheet extrusion equipment

PP/PS sheet single-screw production line: PP/PS sheet single-screw extrusion line is the most mature and stable production solution at present. It generally adopts the form of single machine or double machine co-extrusion, and adopts technology to make this type of machine Comprehensive performance increased by 30%.

The PP sheet production machine produced by GWELL is mainly composed of feeder, single-screw extruder, mold, three-roll calender, mold temperature machine, cooling bracket, trimming machine, traction machine, shearing machine or rewinding machine. Machine composition.

There are many types of our PP/PS sheet production lines.We have PP/PS single-layer sheet production line and PP/PS multi-layer sheet production line.such as ABA, ABCBA, ABCDCBA and other multi-layer structure, which is widely used in heat forming, printing, hardware packaging, electronic tray, flocking, food, clothing, tools, toys, stationery pieces, decorative pieces and so on.

2 . Introduce of PP/PS Sheet production line

PP/PS sheet extrusion production line is common for single-extruder single-layer sheet production line and double-extruder co-extrusion three-layer sheet production line. There are also multi-extruder co-extrusion multi-layer production line, which can process 7-9 layers of composite sheet at most, such as high-barrier EVOH multi-layer co-extrusion production line. This type of extrusion line can process PP, PS, PE and other polyolefin materials.

3. Features of our machine

(1) equipped with precise distributor, evenly layered, adjustable

proportion of each layer, digital precise control.

(2) inclined horizontal structure, easy to operate and maintain.

(3 ) roller independent power, linear speed and extruder speed synchronous closed-loop control.

(4) the whole machine adopts PLC control to realize automatic control of parameter setting, data operation, feedback, alarm and other functions.

(6) Gwell independently wrote the electronic control operating system

4. Machine models

| Type | PP/PS Single extruder production line | PP/PS Double extruder co-extrusion production line | PP/PS multi-extruder co-extrusion production line |

| Extruder type | Optional single screw extruder or twin screw extruder | ||

| Product width | 600mm--1220mm | ||

| Product thickness | 0.15mm - 2mm | ||

| Output | 200kg/h---10000kg/h | ||