Add to Cart

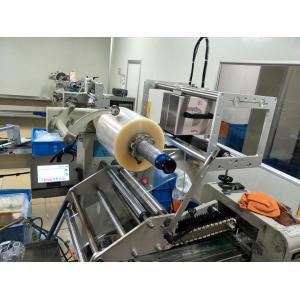

53mmx100mm Printing Area TTO Printer For Packing Production Lines

DIKAI D05S Qr Code Printing Machine Thermal Transfer Overprinter (TTO)

Technical Details:

| Specification | |

|---|---|

| Print Head | Kyocera, 53mm; 300DPI |

| Print Area | Intermittent: 53mm*70mm Continuous: 53mm*150mm |

| Ribbon Size | 55mm*600m |

| Printing Frequency | Intermittent: up tp 350PPM Continuous: up to 40 meters/ minute |

| Environmental Operation Temperature | 0-40℃ |

| Relative Humidity | 10%~95% (non-condensing) |

| Power | AC110~220V, 50/60Hz, 150W |

| Air Supply | 6bar/ 90PSI(MAX) dry uncontaminated |

| Weight | Print head: 8.5kg, Control box: 2.0kg |

| Dimension(L*W*H) | Print Unit: 210mm*210mm*185mm Controller Box: 233mm*180mm*128mm |

What is TTO Printing?

TTO stands for Thermal Transfer Overprinter. TTO Printer is an ideal printing product for most flexible film packaging applications. The printing process produces a very high-resolution code onto the package that is easy to read and ensures no degradation of the aesthetic quality of the packaging film artwork and design.

What are the benefits of thermal transfer overprinter technology?

Improved Print Quality: TTO Printing technology virtually eliminates human error and downtime that occurs when operators incorrectly insert stamps, make spelling mistakes, and lose stamps.

Real -Time Variable Data: TTO Printers contains a real-time clock computer chip, it has the ability to print variable information including dates, lot codes and time.

Increased uptime: TTO Printers design ensures that it is fast and simple to change ribbons and the ribbon length can be very long (up to 1,200m). Software control of ribbon tension and movement (which are critical parameters in any ribbon-based coding technology) ensures the amount of unused ribbon is kept to a minimum.

● Optimizing your benefits:

Can print real-time date, time and batch No.; can edit print text as you want; super 650-meter ribbon reducing the frequency of changing, saving your production time; user friendly interface making it easy to operate; easy-to-learn editing software. Optimizing your Production line and reducing the cost.

● High Quality Print:

High-Resistance Codes: Thermal transfer overprinter can be used in flexible packaging printing creates a highly resistant product that is able to withstand any chemicals, humidity, UV rays, abrasion and climatic changes that your packaging may encounter on its journey through the supply chain.

● Protect your products:

Thermal transfer overprinters will not do harm to the package, extending the valid period; TTO prints clear mark avoids the product being removed from the goods shelf at an early time.

● Protect your Safety:

The cassette of thermal transfer overprinter protects the ribbon and keeps it clean, ensuring the safety of production and products, thus influencing the safety of the company in a profound way.