Add to Cart

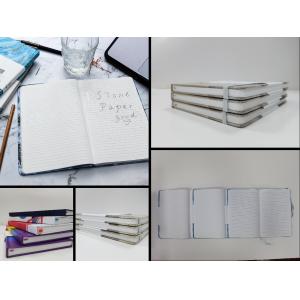

Stone Paper Customized Printing A4 A5 A6 Pocket Size Waterproof Tear Resistant Oilproof Journal eco Friendly Stationery

Stone Paper is made from crushed stone powder, combined with a non-toxic and recyclable binding agent HDPE (High Density Polyethylene). Stone paper is an extremely environmentally friendly paper which is different from traditional paper because it has non wood-pulp.

Making stone paper is a patented paper making technology which will

not pollute air and water.

No chlorine or acids are utilized in the production process, and

the resulting stone paper is completely non-toxic, and is even food

safe.

Unique characteristics

Stone Paper is a new generation of paper and an excellent alternative to traditional paper. it’s tree-free paper that consists almost entirely out of minerals.

1. 100% waterproof

Liquids such as water and oil do not affect Stone Paper.

2. No wood fibers

The swelling of food fibers destroys woodpulp-paper when it comes

in contact with liquid. Result: deformation of the print surface

and a destroyed product.

Stone Paper is 100% waterproof and liquids have no effect on the

material. If it gets wet, you can simply dry it.

3. 100% Tree free. Stone Paper saves trees.

1 ton Stone Paper instead of woodpulp paper means oxygen for 40

people a year.

Completely produced from waste product.

18 trees need to be cut down for 1 ton woodpulp paper.

Stone Paper consists entirely out of waste and recycled material

and therefore has a much lower impact on the environment. For a ton

of woodpulp paper, 18 trees need to be cut down which are then

replaced with fast growing trees that destroy the bio-diversity.

Pulp paper can be recycled 7 times but each process has the same

destructive effect on the environment.

4. Save 2270 liter water

1 ton Stone Paper instead of woodpulp paper means 142 days of

showering.

Stone Paper: Zero water usage

35.000 liters of water is necessary for the production of woodpulp

paper.

During the production of 1 ton of woodpulp paper 2.770 liter out of

35.000 is lost. So using Stone Paper saves 2.770 liter of water,

the equivalent of 50 glasses of water per person per month.

5. Reduce 949kg CO2

During the production of 1 ton of Stone Paper instead of woodpulp,

you save the amount of CO2 that would be expended on a journey of

4.520 km by car.

Stone Paper 482 kg CO2, Pulp papier 1.431 kg CO2.

The CO2 emission from production to end-user: the CO2 emission

caused by the production process, transport and raw materials. The

emission is 67% lower than woodpulp paper. Choosing for Stone Paper

is comparable to preventing the CO2 emission of a trip from

Amsterdam to Jerusalem by car.

6. Save 85% energy

1 ton Stone Paper instead of woodpulp paper means saving the

equivalent energy usage of an average household over 1.5 years.

Stone Paper needs 3,1 Gigajoules, woodpulp paper 20,4 Gigajoules.

For 1 ton Stone Paper you only need 3,1 Gigajoule energy due the

very effecient production process. So the required energy is only

15% of that of woodpulp paper.

7. No chemicals

These chemicals are necessary to bleach woodpulp fibers..

Stone Paper uses no harmful chemicals.

During the production of woodpulp paper, various harmful chemicals

are used to kill the microbes and bleach the material. Stone Paper

requires none of these chemicals.