Add to Cart

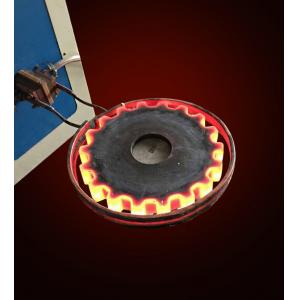

Induction heating equipment is a type of heating system that utilizes electromagnetic induction to heat metal objects. A coil is connected to a power source, and an alternating current is used to create a magnetic field. When a metal object is placed in the magnetic field, it produces its own current, causing it to heat up.

Induction heating is generally used for hardening, tempering, and case hardening of steel pieces, as well as for heating small and irregularly shaped parts that cannot be heated using traditional methods (such as furnaces or gas torches). The equipment normally includes a power source, transformer, control system and a coil. The power source provides the electric energy needed to produce the magnetic field, while the transformer adjusts the voltage provided by the coil. The control system deals with the frequency and intensity of the current to ensure uniform heating.

Induction heating equipment is valued for its energy efficiency, fast heating times and the ability to heat large, complex shapes without causing them any damage. It is extensively applied in the automotive, aerospace and production industries.

Induction heating machines are widely used in various industries for heating metals and alloys, due to their unique and advantageous features.

One of the key advantages of induction heating machines is their fast heating times. They can heat metals quickly, often in just a few seconds or minutes. This is because the heat is generated directly within the material being heated, rather than through the air or a surrounding medium.

In addition, induction heating is an efficient method of heating metals, as it only heats the material that needs to be heated. This results in less energy waste and lower operating costs compared to other heating methods.

Induction heating machines are also equipped with advanced temperature control systems that allow for precise temperature regulation. This ensures consistent heating and minimizes the risk of overheating or underheating the material.

Moreover, induction heating is a non-contact heating method, which means that there is no physical contact between the heating element and the material being heated. This eliminates the risk of oxidation, scaling, or other forms of damage that can occur with other heating methods.

Furthermore, induction heating machines can be used to heat a wide range of metals and alloys, including ferrous and non-ferrous materials. They can also be used to heat small or large parts, as well as complex shapes and geometries.

Finally, induction heating machines are relatively easy to operate and require minimal maintenance. They are also compact and portable, making them ideal for use in a variety of settings.

In conclusion, induction heating machines offer a number of advantages over other heating methods, which make them a popular choice for many industrial applications.

Induction heating equipment is a type of heating system that uses electromagnetic induction to heat metal objects. The process involves passing an alternating current through a coil, which creates a magnetic field around the coil. When a metal object is placed in the magnetic field, it becomes an electrical conductor and generates its own current, which causes the metal to heat up.

The features of induction heating equipment can vary depending on the specific model and manufacturer, but some common features include:

Overall, induction heating equipment is known for its high energy efficiency, fast heating times, and ability to heat large or complex shapes without damaging them. It is widely used in various industries, including automotive, aerospace, and manufacturing.

Induction heating machines have a wide range of applications in various industries because of their extraordinary heating abilities. Some of the common uses of induction heating machines are as follows:

In general, induction heating machines are adaptable and can be utilized in a wide range of industrial applications where precise temperature control and uniform heating are required.

At GY Company, we are committed to providing our customers with the best technical support and service for our induction hardening machines. Our highly trained and experienced staff will work with you to ensure that all of your needs are met.

Our team of engineers and technicians will come to your facility to install the induction hardening machine. They will ensure that all safety protocols are followed and that your machine is set up correctly and ready for operation. They will also provide advice on best practices for running and maintaining your machine.

If you ever encounter a problem with your induction hardening machine, our team is here to help. We offer technical support over the phone or by email, and our team of experts can troubleshoot any issue you may have. If a repair is ever necessary, our technicians can come to your location to fix the problem.

At GY Company, we understand that proper training is essential for safe and efficient operation of the induction hardening machine. We offer comprehensive training programs tailored to your needs. Our team can also provide educational seminars and workshops to help you get the most out of your machine.