Product Details

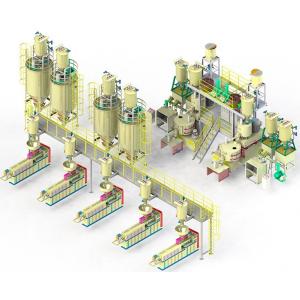

Fully Automatic Powder Mixing Weighing Conveying System For PVC

Pipe Extrusion

Application and introduction

For large PVC pipe/SPC floor/PVC wall panel production factory,

Advanced automatic weighing compounding conveying system is

essential, Traditional mixing method is that people weigh and batch

material manually, then move the mixed material to extruder also

manually, this old way just fit for the small factory, and has many

defects:

1. Artificial mixing system is easy to make a mistake, because this

is a repetition work, so worker is tired easily. the weighing

precision is not assured.

2. Labour intensity is large, human cost is high from long term

view.

3. Chemical raw material harms the worker's health.

In order to solve these problems, our company design this PVC

automatic mixing weighing conveying system which the computer can

automatically control weighing and batching, and feeding compound

to extruder the complete PVC mixing system consists of:

1. Loading station(PVC loader Caco3 loader Recycled material).

2. Pneumatic vacuum conveying system.

3. PVC resin and Caco3 and Recycled material storage silo.

4. Automatic raw material and additives dosing system for mixer.

5. PVC mixing unit.

6. Compound storage silo.

7. Automatic feeding system for PVC extruder.

Automation and storage, automation and discharge:

The storage of large bulk solids quantities is realized in silos,

big-bags and containers, equipped with automatic discharge aids for

a safe extraction of the required product amount from the

container. In case of larger capacities the bags emptying is made

automatically; at smaller discharge capacities the manual discharge

process is usually supported by mechanical devices (likehoists

....).

Automation and conveying:

The application of automation technologies in the field of bulk

solids transport - comprising both mechanical systems (screw

conveyors, bucket elevators, chain conveyors...) and also pneumatic

systems (conveying under overpressure and by vacuum, fluidized bed

chutes...) - has a very strong impact on production and

productivity. It allows to transport even very large bulk

quantities in a reliable and safe manner over great distances

without human intervention.

Automation and metering, automation and weighing:

In the field of metering and weighing the automation allows higher

metering accuracies and has - besides of a productivity increase -

mainly an impact on the product quality. Of great importance are

the production records and batch protocols recorded and filed by

the recipe management system.

Company Profile

Zhangjiagang Chiyu Automation Equipment Co., Ltd focus on building

bulk solid handling plant and supplying related machines and

fabricated parts to plastic, chemical and petrochemical industry.

Our long suits are the best understanding of bulk material

properties and the handling process. We are good at solving

problems which exist in bulk solid conveying, storage, weighing,

mixing and screening.

Meanwhile, offering optimal solutions and proposals of the whole

project. Eventually, our company will provide you with an ideal

project which acts according to your demands.With comprehensive

experience, creative and innovative emotion.