Add to Cart

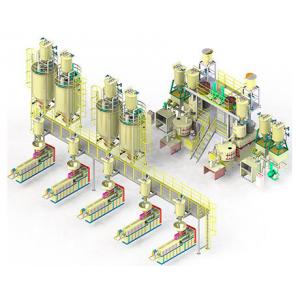

Automatic Feeding Conveying System For Powder Mixer And PVC Extruder

Application and introduction

The PVC materials compounding system is the former part of the PVC production line, which is one of the key to the long-term stable production of the whole line.The automation degree of the compounding system determines the automation degree of the whole production line.

Automatic PVC compounding system is usually composed of the following subsystems: material collection system, material conveying system, metering batching system, mixing unit, material storage equipment,feeding system, dust removal system: central control system, central monitoring system ,etc.The composition and principles of the subsystems are described as below:

| Name | Automatic Feeding System |

| Used for | PVC,food,Chemical,rubber,plastic |

| Material | SUS304,SUS316 |

| Capacity | 300~2000kg/h |

| Feature | High Efficiency High Automation |

| PLC | Siemens 1200 |

1. Automatic PVC Mixing Centralized Feeding System Material collection system

The material collection system is used to collect bulk or bagged raw materials into storage silos in various ways.

Bulk materials can be sent directly to the storage tank through the pneumatic conveying device on the tanker, and the bag materials is collected by the bag opening station.

2. Automatic PVC Mixing Centralized Feeding System Material conveying system

The conveying of the materials is the key to the automation of the compounding and feeding system. In the PVC automatic compounding system, the conveying system occupies a large proportion:Including the conveying from the bagging station to the transition silo upon the batching scales,the finished materials conveying from the mixer to the finished silo ,and also the finished materials conveying from the finished silo to the extruder.

Automatic PVC Mixing Centralized Feeding System Material storage equipment

Material storage equipment are separately silos mainly used for storing raw materials and finished materials.

PVC raw material storage silo has 150m3 of effective volume.The material touching storage materials are all stainless steel,and polished . The outside surface is done with pickling passivation treatment.Consist with silos,dust removal equipment upon the silos ,steel ladder,fences,

decompression cap,gate,and other components etc.

Can automatically control the materials incoming and outgoing by setting the level gauge, it has nice appearance,strong structure,wind proof and other features.In order to ensure the qualified rate of the finished tubes, it is necessary to consider the surplus volume of the finished material’s silos, normally not less than 12 hours, and also the finished material silos’ design adopts the homogenized structure to ensure that the materials are not separated from the stratification.

Automatic PVC Mixing Centralized Feeding System Feeding system for extruder

Feeding system is composed of vacuum feeder or spring feeder.

Vacuum feeder composed of the feeding funnel, suction gun,vortex fan, pulse filter,butterfly valve and storage silos. The biggest rated feeding capacity is more than 1500kg / h.

Spring feeder is a rodless screw conveyor,can be bend in a certain degree, suitable for the feeding for the extruder.