Add to Cart

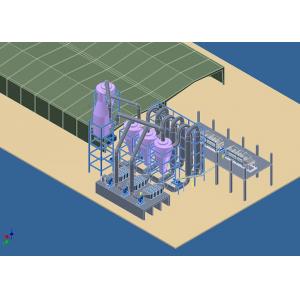

High Drying Efficiency Pneumatic Flashing Dryer Blowing Hot Air

After drying, the commercial pulp board can increase the turnover time and transportation. It is a reasonable choice for paper mills to build overseas pulp bases. Flash drying is an advanced drying form with high efficiency and energy saving. After entering the air duct, the fluffy wet pulp will be suspended under the hot air flow, and will conduct heat and mass transfer quickly, so that the moisture will vaporize instantaneously.

Material

Stainless steel, carbon steel

Product features

Compact structure, small floor area of production line and low investment cost

High drying efficiency, easy transportation and storage of finished products;

High energy efficiency of production line, low investment, low operation and maintenance cost

Functions

In the flash dryer system, the pulp is pressed to 40% dryness by dual web. After being broken by separator machine, it is transferred into flash dryer section through screw feeder and star typed unloader.

The whole flash dryer includes four sections, the first three sections are hot air drying, blowing hot air to dry the pulp board. The last section is the cooling section, blowing the natural air of the mill to cool down the pulp board.

Working principle

When the wet pulp is dried, it is first treated by a fuzzer to fully disperse the pulp and fluff the fiber to obtain the maximum specific surface area, and then sent to the drying duct, where it is suspended in the hot air flow at 150~300 ℃. After 3~5 seconds of drying, the moisture is rapidly evaporated, and finally enters the cyclone separator to separate the hot and humid air. The dryness of the wet pulp can be increased from 40% to 80% by this way, So as to extend the turnover time, reduce the transportation cost and meet the needs of pulping.

Our services

Pre-sale service

After-sales service