Add to Cart

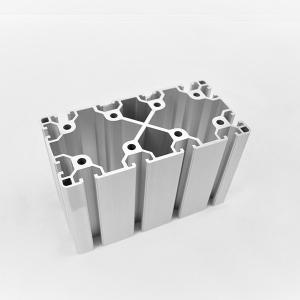

Anodizing Aluminum Extruded Standard Aluminium Profiles Transom Corner Bracket

Description

Designed to withstand demanding industrial environments, our 6063 Aluminum Alloy Profile embodies strength, sophistication, and durability. Meticulously manufactured using premium 6063 aluminum alloy, it exhibits unparalleled resistance to corrosion. Achieve the perfect fit by customizing the profile's size, shape, and color to match your specific requirements. With our efficient production capabilities, we ensure speedy delivery and a monthly capacity of 5000 tons. Choose between standard lengths or personalized options to suit your project. Place your trust in our esteemed brand, Xinjasn, or take advantage of our OEM services.

Specification

| Material | 6063 Aluminum Alloy |

| Temper | T5 |

| Surface Treatment | Mill Finish or Anodizing |

| Size | Customized |

| Place of Origin | Sichuan, China |

| Color | Silver or Customized Color |

| Packaging | Shrink film packaging |

| Shape | Customized |

| Payment Terms | T/T, 30% deposit, balance before delivery |

| Delivery Time | Molding and sample testing: 10-15 days Production Duration: 10-15 days after sample confirmation |

| Capacity | 5000 tons per month |

| Standard Length | 3M-6M |

| FOB Port | Chongqing |

| Application | Industry |

| Brand Name | Xinjasn or OEM |

Why Choose Us?

1.Factory-Direct Prices: Purchase directly from our factory for

cost savings.

2.Uncompromising Quality: Our extensive experience guarantees

top-notch quality.

3.Extensive Mold Catalog: Choose from a vast selection of over ten

thousand molds.

4.Tailored Solutions: Custom molds are available to meet specific

requirements.

5.Streamlined Production: Our integrated approach ensures

efficiency and value.

6.ISO-Certified Excellence: We hold an ISO 9001:2015 certification

for quality.

7.Industry Expertise: Rely on our years of experience and

knowledge.

8.Premium Surface Finish: Advanced equipment for superb surface

quality.

9.Your Design, Our Expertise: We can extrude profiles from your

provided drawings.

10.Trusted Partner: Depend on us for consistency and excellence in

aluminum profiles.

Product Introduction

| Customized: We offer a flexible mold opening service tailored to your specific requirements. To initiate the process, all we need is a sample,a CAD drawing or the precise dimensions you desire for the mold. | |

| Ready-to-use molds: Small size (2020 to 4040) Medium size(4040 to 8080) Large size(8080 to 16040) | |

| Surface treatment--Anodizing: 1. Anodizing is an electrochemical process that convertsthe metal surface into a decorative, durable, corrosion-resistant, anodic oxide finish. 2. The thicker the anodic layer created, the greater thecorrosion resistance 3. Anodizing colours:Silver white, black, gold,platinumgrey, sandblasted siver white... |

Product superiority

1.Our post-treatment methods include anodizing, powder coating,

wood grain, and electrophoresis, providing a diverse range of color

choices for our aluminum profiles.

2.In addition to popular colors like black, white, champagne, and

bronze, we can match specific colors based on Pantone codes. This

level of customization allows us to create visually stunning and

unique finishes.

3.The extensive range of color choices provided through our

post-treatment methods ensures that our customers can achieve their

desired appearance and create aluminum profiles that perfectly suit

their needs.

Our advantages

1.With a manufacturing experience of over 15 years, we have honed

our expertise in producing aluminum profiles.

2.Our dedicated team of highly skilled professionals is committed

to providing exceptional service and meeting your needs

effectively.

3.Our products undergo stringent quality control processes,

ensuring compliance with ISO9001, ISO14001, and IATF16949

standards.

4.Choose from an extensive range of readily available molds,

offering versatility and options to suit your requirements.

5.Our comprehensive one-stop service covers all stages, from design

and mold making to extrusion, powder coating, anodizing,

electrophoresis, wood grain transfer, packaging, and timely

delivery.

| Company Introduction | ||

| Sichuan Xinjiasheng Aluminum Company was established in 2009 and boasts an extensive area covering over 100,000 square meters. As one of the leading and professional manufacturers in the industry, we excel in integrating research, design, production, and sales of aluminum alloy architectural profiles and industrial aluminum profiles. Our state-of-the-art production equipment encompasses aluminum alloy casting, mold making, aluminum extrusion, powder coating, anodizing, electrophoresis, and wood grain transfer. Our product range includes both standard aluminum profiles and customized profiles, allowing us to extrude profiles according to your provided drawings or samples. At Xinjiasheng, we take immense pride in our ISO 9001:2015 certified facilities, specifically designed to produce finished parts made from aluminum extrusions. Quality is ingrained in every aspect of our operations, from start to finish. | ||

| Factory Area:100,000 ㎡ Employees: over 600 Extrusion Line:14 Annual production:50000 Tons Thousands of ready-to-use molds | ||

Workshops

Inspection equipments

FAQ

Are you a manufacturer or a trading company?

A: We operate as a well-established manufacturer with over 15 years

of industry expertise.

Where is your factory located?

A: Our factory is conveniently located in the Aluminum Silicon

Industrial Zone, Xiuwen Town, Meishan City, Sichuan Province,

China.

How do you provide quotations?

A: Quotations can be obtained by submitting a sample or drawing in

CAD/STP/IGS format. Once we have assessed the material and surface

treatment requirements, we will promptly generate a quote for your

consideration.

What is the lead time for manufacturing new molds?

A: Typically, our lead time for developing new molds is 7-15 days.

Do you offer samples? If yes, is there a cost associated?

A: Yes, we offer samples at no cost. However, the customer is

responsible for covering the freight charges.

What is your delivery time?

A: The process of mold development and sample confirmation usually

takes 12-15 days. Following the receipt of the buyer's deposit, the

production duration is approximately 15-25 days.

Do you accept OEM or ODM orders?

A: Absolutely, we gladly accept both OEM (Original Equipment

Manufacturer) and ODM (Original Design Manufacturer) orders.