Product Details

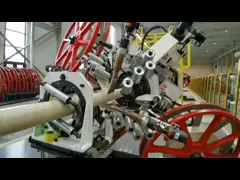

Continuous fiber reinforced thermoplastic adhesive composite pipe

(DN200-500)

Continuous fiber reinforced thermoplastic adhesive composite pipes

are designed to address the problems of severe corrosion, short

service life, high maintenance costs, low pressure resistance, low

temperature resistance, and small diameter of traditional

non-metallic pipes in gathering and transportation pipelines.

The bonded composite process improves the overall mechanical

performance of the composite pipe, with a higher pressure

resistance level and stronger resistance to external pressure

deformation compared to traditional non bonded flexible composite

pipes, and a larger manufacturing diameter; Better impact

resistance, tensile resistance, and gas permeability resistance;

The integral pipe wall structure can be welded by non-metallic

sleeve electric heating fusion. This non-metallic reinforced joint

connection technology completely solves the problem of traditional

flexible pipe metal joints being prone to corrosion, enabling the

service life of both the joint and the pipe body to reach over 20

years

Pipeline inner layer: corrosion-resistant, wear-resistant,

conductive, and stress conductive.

Pipeline core layer: bears the effects of internal pressure,

external pressure, axial stress, and lifespan.

Pipeline surface layer: resistant to impact, wear, and UV

radiation.

Company Profile

Baoji Tianlian Huitong Composite Materials Co., Ltd. is focused on providing specialized continuous composite pipes for

the energy industry. The company is a national high-tech enterprise

and a national-level specialized, refined, and new "little giant"

enterprise. It has leading comprehensive production capacity and

technology research and development strength in China.

The company is a provincial-level technology center in Shaanxi

Province and has long-term cooperation with research institutions

such as the China Petroleum Engineering Materials Research

Institute (Xi'an Pipe Institute), Aerospace 43rd Institute of China

Aerospace Science and Industry Corporation, Zhejiang University,

China University of Petroleum, Chang'an University, and Xi'an

Shiyou University, to jointly conduct research and development of

non-metallic composite material process technology,

polymer-modified materials, and supporting equipment. As of 2022,

the company has obtained 26 technology patents. By December 2022,

it has accumulated 8,000 kilometers of experience in manufacturing,

installation, and operation of flexible composite pipes.

The company is a Class A supplier of China Petroleum and a Class A

credit supplier of Sinopec. It is also a network supplier of State

Energy Group, China National Coal Group, and Shaanxi Coal Group.

The company has a market share of over 20% in the domestic oil and

gas field market. Its products have been widely used in major oil

and gas fields in China and overseas regions such as the EBS oil

field in Iraq and the Akdala oil field in Kazakhstan, and have

received unanimous praise from customers.