Add to Cart

Aluminium Board Panel - Fire Rated ACP Sheet, 6.0mm Thickness, 0.3mm Aluminum, Stone Grain Surface

DESCRIPTION

The aluminum plastic composite is a unique blend of two divergent materials - metal and non-metal, ingeniously synthesizing the optimal attributes of both. It retains the key characteristics of the original materials, such as aluminum and polyethylene plastic, and overcomes their shortcomings to realize a multitude of superior material properties. This includes its luxurious allure, vibrantly colorful decorativeness, weather resistance, corrosion resistance, impact resistance, fireproofing, dampness resistance, sound insulation, heat insulation, and seismic resistance. Additionally, it features a lightweight construction, ease of manipulation, and convenient transport and installation.

Company Profile

Our company, founded in 1999, integrates sophisticated continuous extrusion equipment. With a wealth of expertise, we have a seasoned team producing top-tier Aluminum Composite Panels, used in numerous architectural and decorative applications. Commitment to quality has endowed our offerings with unrivaled features, resonating with modern aesthetic trends. Emphasizing international standards, we take pride in our ISO 9001:2008 and various other honors. We cherish collaborations with research institutions and industry peers, seeking continued patronage. "Richly Bound" symbolizes our diverse decorative products, consistently meeting national standards. Being a market leader, our products enjoy acclaim across China and nearby regions. Nestled close to Hong Kong and Macao, we're poised for global partnerships.

Product Features

1.Light-as-a-feather Construction: Aluminum-plastic panels, due to

their light-as-a-feather construction, are a favorite in the

building and decorating sector. Their lightness allows for easy

installation and transportation, leading to a reduction in

construction expenses. Despite their lightness, they remain sturdy

and long-lasting.

2.Exceptional Weatherproof Qualities: With their exceptional

weatherproof qualities, aluminum-plastic panels can withstand harsh

weather conditions, including intense sunlight, wind, rain,

humidity, and temperature variations. This makes them an excellent

choice for outdoor building and decorating projects.

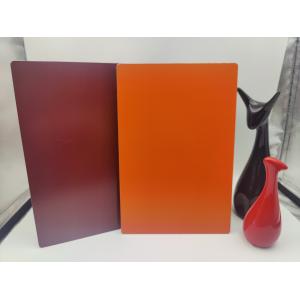

6.Multitude of Colors and Styles: Aluminum-plastic panels come in a

multitude of colors and styles to satisfy various aesthetic tastes.

The surface of this material can be manipulated in several ways,

including spraying, coating, and printing, to create distinctive

visual aesthetics.

4.Low-maintenance and Easy to Clean: The surface of the

aluminum-plastic panel is sleek and resistant to dust and grime

accumulation. Cleaning it is as simple as using a detergent and

cloth. This material requires no special maintenance and can keep

its original appearance and performance for a long time.

5.Environmentally Conscious: Aluminum-plastic panels are an

environmentally conscious material that doesn't release harmful

substances. Additionally, its recyclability is a boon to

environmental preservation.

6.Superior Soundproofing: Aluminum-plastic panels offer superior

soundproofing, reducing noise transmission. This makes them highly

beneficial in places where sound insulation is required, such as

offices, hospitals, and schools.

7.Fire-resistant: Aluminum-plastic panels have excellent fire

resistance. In a fire, they can prevent the spread of flames and

protect the structural safety of buildings.

Application fields

1.Building Skins: Surface solutions for towering infrastructures, personal homes,

office blocks, and shopping high-rises.

2.Decorative Inlays: Interior revamps in personal, professional, and retail atmospheres

using wall treatments, canopy arts, and space segments.

3.Brand Displays: Crafting visible promotions, frontage labels, guiding markers,

printed visuals, and podium setups.

4.Voyage Traffic: Essential in the body-making of road buses, track vehicles,

underground transits, air vessels, and ocean liners.

5.Interior Craft: Molding contemporary fixtures, dressers, gourmet units, and house

add-ons.

6.Workshop Spaces: Mechanism shields, tool covers, and in hygienic working zones.

7.Trade Displays: Curating shopper-friendly atmospheres, service stands, and product

showcases.

8.Leisure Establishments: Redefining stay areas, relaxation spots, and dining spaces.

9.Treatment Buildings: External applications in healing hubs and wellness centers valuing

cleanliness and durability.

10.Knowledge Hubs: Usage in learning centers for informational tools, functional

furniture, and creating zones.

11.Entertainment Sectors: Requirements in play areas, fitness centers, and activity spots.

12.Travel Points: Designs and guidance tools in fly zones, track junctions, road

stops, and maritime stations.

Product processing performance

Our company's manufactured aluminum composite panels are versatile in their adaptability to a range of woodworking and metalworking tools. These tools facilitate operations like cutting, sawing, milling, stamping, pressing, folding, and bending. Such adaptability makes it feasible to achieve architectural design requirements, particularly for unique forms like arcs, counter-arcs, tight-radius edges, and both inner and outer corners. Few other decorative materials offer such a diverse range of applications.

1.For Cutting: Tools include hand saws, electric saws, and circular

saws.

2.Groove Milling: By utilizing a portable milling machine, it can

be hand-bent to form polyhedral shapes.

3.Edge Trimming: With punching and edge trimming tools, integration

into a structure becomes feasible.

4.Fusion: Fusion is possible using hot air tools and plastic

welding rods.

5.Angle Forming: Post milling, various angular forms can be

achieved.

6.Flexing: The 3-point or 3-roll machines are efficient for bending

processes.

7.Graphic Application: Screen printing techniques can be used for

graphic applications.

8.Joining: Techniques involve rivets, nails, and screws.

9.Hole Creation: An open puncher tool facilitates hole creation.