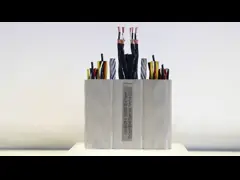

Subsea Composite Power Cable Lead Sheath Submarine Power Cable

Add to Cart

Product Description

Shanghai Qifan Subsea Composite Power Cable (Lead Sheath) submarine cable

submarine power cable is a major transmission cable for carrying electric power below the surface of the water. It is also possible to use submarine power cables beneath fresh water.Yichang Qifan Cable Co.,ltd.,a wholly-owned subsidiary of Shanghai Qifan Cable.,ltd. Was established on October 2020. with a registered capital of RMB200 million, The company is close to the world-famous Three Gorges Power Station, It currently has about 300 employees, The plant covers an area of about 450,000 square meters and has an annual production capacity of more than RMB 3 billion, It has a 400-meter-long submarine cable transport plank road leading to the Yangtze River docks.

Yichang Qifan Cable has a VCV line with tower height measuring more than 180 meters and a series of advanced high-voltage cable and submarine cable production equipment capable of manufacturing onshore and submarine power cable of 500KV and below, They include

√ Two Finnish MAILLEFER high-voltage cable VCV production lines

√ A German TROESTER high-voltage cable VCV production line

√ Two Finnish MAILLEFER medium-voltage cable CCV production Lines,

√A French POURTIER frame type wire standing machine and a drum twister machine

Construction

System voltage: U≤33kV

Conductor: Circular stranded copper or aluminum conductor constructed of round or profiled wires.

Insulation: Cross-linked polyethylene (XLPE) or TR-XLPE

Metallic Screen: Copper wire, copper tape and lead alloy sheath , etc.

Radial water barrier: Semi-dry design: Laminated aluminum foil

Dry design: Lead alloy sheath

Wet design: PE sheath

Armor: Three-core: Galvanized steel wire

Single-core: Magnetic galvanized steel wire,

Non-magnetic HD copper wire, stainless steel wire

Armor bedding & serving: Polypropylene yarn

System voltage: | 30kV≤U≤500kV |

Conductor: | Circular stranded copper or aluminum conductor constructed of round or profiled wires. |

Max. CSA 3000sq.mm | |

Insulation: | Cross-linked polyethylene (XLPE) |

Metallic Screen: | 30kV≤U≤66kV: Copper wire, lead alloy sheath |

U≥110kV: Lead alloy sheath | |

Radial water barrier: | Semi-dry design: Laminated aluminum foil |

Dry design: Lead alloy sheath | |

Armor: | Three-core: Galvanized steel wire |

Single-core: Magnetic galvanized steel wire; Non-magnetic HD copper wire, stainless steel wire | |

Armor bedding & serving: | Polypropylene yarns |

Types & Purposes

For offshore wind farm

-Export cable to transport the total generated power from offshore

substation to onshore substation

For interconnection

-Interconnecting grids of countries

-Power supply from mainland to isolated islands

Main products: 220kv and below power cables, rubber sheathed cables, photovoltaic wires, photovoltaic special cables, control cables, computer cables, steel core aluminum stranded wires, pre-branch cables, low voltage halogen-free environmentally friendly cables, coal mining cables, fluorosilicone insulation High temperature resistant cables, shield cables, cables for ship electrical equipment, photoelectric composite cables, high-strength towing cables, cables for photovoltaic systems, cables for rail transit vehicles with AC rated voltage 3kv and below, local area network cables, inverter cables, radio frequency cables , nuclear power plant cables, port machinery cables, mineral insulated cables, submarine cables and more than 100 varieties

1.30 years production experience

2.Products certification

:UL,CE,BV,TUV,KEMA,PSB,SABS,ABS,NK,LR,KR,GL etc

3. OEM service available based on official & legal authorization.

4.Strict quality control system.

5.Rapid delivery and feedback Faster lead time than our

competitors.

6.Excellent quality with reasonable price.

7.Strong technical support (technical data, drawing, etc.)

8.Professional teamwork service for you actively.

9.Stock available, Free sample is available.

Submarine cables are primarily used for long-distance

communication, connecting different continents and countries. They

enable the transmission of large volumes of data, including

internet traffic, telephone calls, and other forms of

telecommunications.

Construction: Submarine cables are constructed with multiple layers

of protective materials to ensure their durability and performance

in the harsh marine environment. The typical construction includes

a conductor, insulation, metallic shielding, and an outer

protective sheath.

Transmission Capacity: Submarine cables are capable of carrying

large amounts of data or electrical power. They have high

transmission capacities, often measured in terabits per second

(Tbps) for data cables and gigawatts (GW) for power cables.