TM System Polyurethane Polyol And Isocyanate For High Resilience Cushion Foam

Add to Cart

TM system PU high resilience car seat foam

JYHR-21A/B

Introduction:

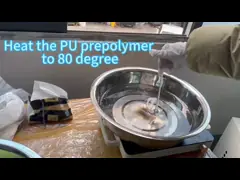

JYHR-21A is made up of polymer polyol, grafted polyether polyol, cross linker, blowing agent, and composite catalyst. JYHR-11Bis made up of modified MDI and TDI. This type of blend polyol can be used under mold-temperature 60-70℃, mould material should be aluminum or steel which enjoy excellent sealing ability. The finished foam enjoys low density, good rebound, comfortable feeling ect.

And the hardness and density can be adjusted by customer requirement. It’s widely used to produce cushion, motor bike seat foam, car seat foam etc.

Typical Properties

| Item Unit | JYHR-21A | JYHR-21B | |

Appearance OHV NCO Viscosity(25℃)Density (20℃) Storage temp. Shelf life | mgKOH/g % mpa.s g/ml ℃ Months | Milky white liquid 42±2 / 1200±200 1.05±0.05 15-25 12 | Brown liquid / 40±2 10±5 1.22±0.05 15-25 12 |

- *Under the recommending temperature, keeping in the original dry barrels of storage; B-side is suggested using nitrogen seal save as much as possible after opening.

Recommended ratio

| Weight ratio | |

BRHR-11A BRHR-11B | 100 45-50 |

REACTIVE PROPERTY (Material temperature is 25℃)

| By hand | Machine | ||

Cream time (s) Gel time (s) Mold temperature (℃) Demould time (min)FRD (kg/m3) | s s ℃ min kg/m3 | 7— 9 50-60 60-70 4-6 35-40 | 6-8 45-55 60-70 4—6 35-40 |

TYPICAL PHYSICAL PROPERTY

| Unit | Data | |

Moulded density Tensile strength Elongation (%) Rebound Tear strength 75% Compression Set (70℃ ,22h) 25% ILD (N/314cm2) 65% ILD (N/314cm2) | Kg/m3 Kpa % % N/cm % N/314cm2 N/314cm2 | 45-55 ≥112 ≥95 ≥50 ≥2.0 ≤10 150-200 400-700 |

- The above technical data are tested by our own, is not subject to any restriction in law.

The final interpretation of this specification is owned by our company.