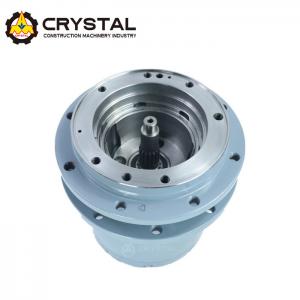

PC18 Excavator Travel Gear Box Industrial Hydraulic Motor Gear Reducer

Add to Cart

Excavator Hydraulic Parts Komatsu PC18 Travel Reduction Final Travel Gear Box

Product Description

Provide or customize the required products according to customer's

requirements | |||

Product Name: | Travel gearbox | Model Number: | PC18 |

Condition: | OEM/Original New | Delivery: | Within 1-3days |

Inventory: | In stock | Place Of Origin: | China |

Packing: | Wooden Case | Payment Term: | L/C,T/T.Western Union |

We will check the goods and send detail message to buyer to confirm

before shipping. | |||

Applicable model

Cooperative Brands | Available Model |

HYUNDAI | R55 R60 R80 R130LC-3-5 R200 R200-5 R210 R215-7/9 R220-5 R225LC-7/9

R290 R290 R290LC-7 R300LC R305LC R330LC R375 R360LC-7 R450LC |

ZXAIS/HITACAI | EX35 EX40 EX55 EX60 EX60-3 ZX200 ZX210 ZX250 ZX290 ZX330 ZX470

EX1000 EX1200 |

VOLVO | EC55 EC60 EC140BP EW145BP EW160BB EC210 EC240 EC290 EC360LC

EC380.EC460 EC480 EC700 |

CATERPILLAR | CAT305.5 CAT306 CAT307 CAT308 CAT312 CAT315 CAT320 CAT323 CAT324

CAT325 CAT326 CAT330 CAT336 CAT345 CAT349 CAT365 CAT374 CAT390 |

KOMATSU | PC45 PC50 PC55 PC56 PC60-5-6-7 PC60-8 PC70-8 PC78 PC100-3 PC120-6

PC130-7 PC200-7/8 PC220 PC270 PC240 PC300-6/7 PC360

PC400-6/7/8PC450-6 PC600-6 PC650-3 PC650 PC800 PC1000 PC1200 PC1250 |

KOBELCO | SK35 SK50 SK60 SK75 SK100 SK120 SK200-1-2-3-4-5-6 SK230 SK250 SK260

SK280 SK300 SK330 SK330-6 SK350 SK400 SK450 SK480 |

DOOSAN/DAEWOO | DH35 DH55 DH60 DH55 DH60 DH80 DH80-7 DH80GOLD DH150 DH200 DH220-3-5

DH280-5 DX60-DX200-DX225 DX260 DH290 DH360 DH420 DH500 |

SUMITOMO | SH55 SH60 SH75 SH50 SH100 SH120 SH200 SH200-3-5 SH220-2-3 SH280

SH300 SH350 SH400 SH450 |

KATO | HD820 HD1023 HD1430 HD2045 HD700 |

SANY | SY55 SY60 SY65 SY70 SY75 SY85 SY95 SY115 SY135 SY155 SY195 SY200

SY205 SY215 SY220 SY225 SY235 SY245 SY285 SY305 SY335 SY365

SY375SY395 SY415 SY485 |

LIUGONG | CLG904 CLG9055 CLG906 CLG907 CLG9075 CLG908 CLG915 CLG150 CLG920

CLG921 CLG922 CLG225 CLG924 CLG925 CLG933 CLG936 CLG939

CLG942CLG948 CLG950 CLG952 CLG200 CLG205 CLG220 CLG225 |

KUBOTA | KX135 KX185 KX155 KX161 KX163 KX165 KX183 |

IHI | IHI35 IHI50 IHI60 IHI55 IHI80 IHI100 |

XCMG | XE55 XE60 XE65 XE75 XE80 XE85 XE135 XE150 XE155 XE200 XE205 XE215

XE225 XE245 XE270 XE305 XE335 XE370 XE380 XE400 XE470 XE490XE700 |

YANMAR | ViO35 ViO55 ViO75 |

CASE | CX50 CX55 CX58 CX75 CX210 CX240 CX290 CX330 |

YUCHAI | YC35 YC50 YC55 YC60 YC65 YC85 YC135 YC230 |

JCB | JS130 JS210 JS220 JS290 JS330 |

Product technology

In the field of modern engineering construction, excavator is an indispensable key equipment. As the core component of the excavator walking system, the excavator walking motor gear box's exquisite technology is an important guarantee for the efficient operation of the excavator.

1.high precision processing technology:

CAD design: The production of excavator travelling motor gear box

starts from the CAD (computer aided design) stage. CAD software can

accurately draw the design drawings of each part to ensure that the

geometry and size of the gear box are accurate.

CNC machining: High precision CNC machining technology is the key

to manufacturing high-quality gear boxes. Through CNC machine

tools, precise cutting and machining parts, to ensure the accuracy

and fit of each gear, bearings and other components.

2. Selection of high-quality materials:

High quality alloy steel: excavator walking motor gear box is

usually made of high quality alloy steel material, with excellent

strength and wear resistance. This material can maintain the

structural integrity and durability of the gearbox under high loads

and harsh conditions.

Surface treatment: In order to increase the corrosion resistance

and surface hardness of the gearbox, heat treatment, surface

hardening and other processes are often used to ensure that the

gearbox is still stable in harsh environments.

3. precision assembly and commissioning:

Assembly process: The assembly process of excavator walking motor

gear box is very complicated. Manufacturers usually use

professional assembly lines and assembly processes to ensure

accurate assembly of each component and avoid failures caused by

improper assembly.

Strict debugging: After the completion of assembly, the gearbox

needs to go through a strict debugging process. Through

professional testing equipment and testing means, ensure that the

performance and operation of the gear box meet the design

requirements.

4. Quality control and testing:

Strict quality inspection: In the production process, the excavator

walking motor gear box goes through multiple quality inspection

processes to ensure the conformity of each process link.

Comprehensive testing: Each gearbox is comprehensively tested

before leaving the factory, including noise testing, vibration

testing, temperature testing, etc., to verify its stability and

reliability in the real working environment.

he exquisite technology of excavator travelling motor gear box is

an important guarantee for the efficient operation of excavator.

Through high precision machining technology, high-quality material

selection, precision assembly and commissioning, as well as strict

quality control and inspection, the gearbox can operate stably in

harsh engineering environments, providing a strong driving force

for engineering construction. In the future, with the continuous

progress of science and technology, the process of excavator

walking motor gear box will continue to innovate, and contribute

more wisdom and strength to the development of construction

machinery.

Our advantage

Excavator is the right hand of engineering construction, and its

traveling motor reducer is the core component to ensure the

flexible action of excavator. With advanced technology and superior

performance, excavator travelling motor reducer has set a technical

benchmark in the field of construction machinery.

First, high torque output:

Exquisite design: excavator walking motor reducer through exquisite

technology and design, to achieve high torque output. This means

that the motor can provide a strong driving force under high loads

and complex terrain, making it easy for the excavator to cope with

a variety of engineering tasks.

Superior stability: High torque output brings stronger driving

force, making the excavator walk more stable, can maintain good

driving performance in different terrain and working conditions,

and improve work efficiency and safety.

Second, high efficiency and energy saving:

Optimized transmission system: excavator walking motor reducer

adopts advanced transmission system optimization design to reduce

transmission loss and improve energy efficiency. Under high load

and long working time, it can reduce fuel consumption and extend

the service life of the hydraulic system.

Intelligent throttling technology: The travelling motor reducer is

equipped with intelligent throttling technology, which can adjust

the hydraulic flow according to the actual working conditions and

reduce the energy consumption of the system. This energy-saving

technology is very important for long working hours and

high-intensity construction, helping to reduce engineering costs.

Third, precision manufacturing and reliability:

High quality materials: The excavator walking motor reducer is made

of high quality alloy steel and special wear-resistant materials to

ensure its durability and wear resistance. This high-quality

material provides stability and reliability in harsh engineering

environments.

Strict inspection and testing: The travelling motor reducer has

undergone strict inspection and testing in the production process

to ensure that its indicators meet the design requirements. Through

the reliability test, the reliability and stability of the motor in

various working conditions can be verified.

Four, intelligent control:

Adaptive system: The modern excavator walking motor reducer is

equipped with an intelligent adaptive control system, which can

adjust the output in real time according to the working conditions,

adapt to different work needs, and improve work efficiency.

Fault diagnosis and prediction: The travelling motor gearbox has

intelligent fault diagnosis and prediction function, which can

monitor the system status in real time, find potential faults in

time and provide solutions. This helps reduce downtime and

increases productivity and reliability.

Excavator walking motor reducer with high torque output, high

efficiency and energy saving, precision manufacturing and

reliability, as well as intelligent control and other technical

advantages, has become an indispensable power source for excavator

walking system. Its excellent performance and stable operation

provide a strong driving force for engineering construction. In the

future, with the continuous progress of technology, excavator

walking motor reducer will continue to innovate and lead the new

trend of development in the field of construction machinery.

certificate

Our products meet international standards, is a national key enterprise in China, we will be more advanced products to the world, service customers all over the world.

More products Show

If you have more needs, we can also provide you with customized services, our products are under continuous development to ensure the continuous needs of customers.

Delivery and logistics

| Net weight | 23KG |

| Package | wooden |

| Mode of transport | By sea, by air |

| Payment term | TT bank transfer,L/C |

| Warranty time | Half a year |

| Delivery time | Have in stock,within 3-5 days to ship it out |

Our Services

Dear Customer,

Thank you for your interest and trust in our hydraulic walking device products and services. We are a company specializing in the production of high-quality hydraulic walking devices and have accumulated years of experience and technical expertise in this field. Our products are not only reliable in quality, but also perform well in terms of performance, safety and durability.

Our service concept is customer-centric, with the goal of meeting customer needs, adhering to the service philosophy of "integrity, professionalism, efficiency, and innovation", and always maintaining communication and exchange with customers to ensure customer satisfaction and trust. Our team is composed of experienced, skilled, and enthusiastic professionals who provide customers with comprehensive service support, including:

1. Customization of products: We can provide customers with customized hydraulic walking device products tailored to their needs and requirements to ensure that the products meet the customer's usage and environmental requirements.

2. Technical support: We have a professional technical team that can provide customers with technical support for product selection, installation and commissioning, maintenance and other aspects to ensure that customers can use our products smoothly.

3. After-sales service: We provide 7x24-hour after-sales service to ensure that customers can get timely solutions to any problems encountered during use.

Our products have been exported to overseas markets and have won unanimous praise from customers. We believe that through our professional technology and high-quality services, we can become your trusted long-term partner.

If you have any needs or questions about our products and services, please feel free to contact us. We will provide you with the best service and support and look forward to working with you!

Contact us

EMAIL:Bing83125@gmail.com

Whatsapp:8619554163292 8615805343909

FAQ

1, Q: Are you a manufacturer or a trading company? A: We are a manufacturer of quality final drives located in Qingdao

National High-Tech Industrial Development Zone with 14 years of

production experience .

2. Q: What is your company size ? A: Ours factory covers an area of 70,000 square meters with 120

employees . Turnover of 2019 is 20 million USD .

3, Q: What certificate do you have? A: ISO9001 / EN ISO 12100 / OHSAS 18001 / SGS

4, Q: How long is your delivery time? A: We keep stock for conventional products . New orders to produce

takes about 20 days. Customized products takes about 40 days .

5, Q: What kind of payment terms do you accept? A: T.T. / DP at sight / LC .

6, Q: What is your warranty policy? A: All our products are warranted for one full year from date of

delivery against defects in materials and workmanship.