Add to Cart

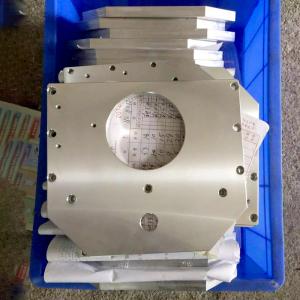

CNC Stainless Steel Machining Service CNC Custom Machining Part CNC Machining Part

We possess the expertise to CNC machine a wide range of components, from straight forward

"as machined" workholding fixtures to intricate geometries.

Our manufacturers utilize a comprehensive array of CNC milling and turning centers, and we

can also accommodate EDM and grinding upon request.

Our capabilities extend to achieving tolerances as tight as 0.05 mm (0.0020 in), and we can

deliver within lead times as short as 3 business days.

Product Details

The CNC machining process predominantly employs metals as its primary materials.

These metals encompass alloy steel, carbon steel, cast iron, stainless steel, aluminum, copper,

magnesium, and zinc.

Nonetheless, this versatile process can also be applied to machine plastic components and work

with an array of other materials, including ceramics, composites, thermoplastics, and thermosets.

Here is a comprehensive overview of the most popular materials

| The Most Popular Materials | |

| Material | Characteristics |

| Aluminum 6061 | Good strength-to-weight ratio, excellent machinability, low hardness |

| Stainless Steel 304 | Excellent mechanical properties, resistant to corrosion & acid, relatively difficult to machine |

| Brass C360 | High ductility, excellent machinability, good corrosion resistance |

| Copper | Excellent thermal and electrical conductivity |

| Titanium | Excellent strength to weight ratio, used in aerospace, automotive and medical industries. |

| ABS | Excellent impact resistance, good mechanical properties, susceptible to solvents |

Nylon (PA6 & PA66) | Excellent mechanical properties, high toughness, poor moisture resistance |

| POM (Delrin) | High stiffness, excellent thermal & electrical properties, relatively brittle |

Surface Finishing

We specialize in the production of custom-made products and offer surface treatment services

tailored to meet our customers' specific requirements and industry standards.

Our comprehensive solutions are both efficient and cost-effective, making us a one-stop destination

with the capacity and capability to provide integrated services.

| Surface Finishing Options for CNC Machining | ||

| Name | Applicable Materials | Can be Applied with |

| Alodine | Aluminum | Media Blasting, Tumbling, Type II Anodizing* Type III Anodizing*, Type III Anodizing with PTFE* |

| Anodizing | Aluminum | Media Blasting, Tumbling, Alodine* |

| Black Oxide | Steel, Stainless Steel | Media Blasting, Tumbling, Passivation |

| Electroless Nickel Plating | Aluminum, Steel, Stainless Steel | Media Blasting, Tumbling |

| Electropolishing | Steel, Stainless Steel | — |

| Hand Polishing | Acrylic | Enhanced cosmetic appearance |

| Media Blasting | Aluminum, Steel, Stainless Steel, Brass, Bronze, Copper | All post processes except Electropolish and Powdercoat |

| Nickel Plating | Aluminum, Steel, Stainless Steel | Media Blasting, Tumbling |

| Passivation | Steel, Stainless Steel | Black Oxide, Electroless Nickel Plating, Zinc Plating, Tumbling, Media Blasting |

| Powder Coating | Aluminum, Steel, Stainless Steel | — |

| Tumbling | Aluminum, Steel, Stainless Steel, Brass, Bronze, Copper | All post processes except Electropolish and Powdercoat |

| Vapor Polishing | CNC Polycarbonate (Clear, Black) | Enhanced cosmetic appearance, near optically clear applications |

| Zinc Plating | Steel, Stainless Steel | Media Blasting, Tumbling, Passivation |

Specialist Industries

Industries Benefiting Most from CNC Machined Parts

1. Electronics Industry

CNC machines and milled parts are vital for crafting electronic

enclosures, circuit supports,

and related components in the electronics sector.

2. Commercial Industry

CNC cutting heads enable cost-effective production of commercial

parts, reducing production

expenses and saving time. Manufacturers often utilize milling services for creating a wide range

of mechanical components.

3. Oil and Gas Industry

Petrochemical companies rely on these machines to manufacture drill

bits, cylinders, pins,

rods, valves, and various other critical components.

4. Medical Industry

CNC milling tools are instrumental in producing various medical

parts, including implants and

medical devices. Surgical equipment and components like ventilator parts, insulin pumps, medical

rods, implants, bone plates, and medical screws are frequently created using CNC milling.

5. Aerospace Industry

The aerospace sector continually demands CNC machined parts. These

machines excel at crafting

complex, customized components for aerospace equipment, including electronic enclosures,

landing gear, hydraulic manifolds, housings, fuel bodies, and bearing houses.

Company Profile

FAQ's

1. How does our pricing compare to other suppliers?

When it comes to pricing, making direct comparisons can be challenging.

However, as a general guideline, our prices for plastic injection mold tools and CNC

machined/turned parts are typically 25-45% lower than those of suppliers in North America

and Europe.

In contrast to Chinese suppliers, we prioritize delivering the utmost quality, swift response

times, and professional outcomes, rather than engaging in a price-driven competition.

2. How soon can I receive my parts?

We can produce high-quality parts in as little as two weeks if you furnish us with comprehensive

2D and 3D CAD models.

However, for more intricate parts with additional requirements or special features, the lead time

may be longer. Feel free to request a quote to obtain precise lead times tailored to your project.

In terms of shipping, the majority of our shipments are dispatched via air freight. The transit time

from China to Europe or North America typically takes a few days.

3. What tolerances can achieve?

Tolerances are not universally fixed and vary depending on the specific processes and materials

involved. The final tolerances for your part are influenced by several factors, including:

1. Part Size

2. Design Complexity

3. Number, Type, and Size of Features

4. Material(s) Used

5. Surface Finish Requirements

6. Chosen Manufacturing Process

Upon order confirmation, we conduct a Design for Manufacturing

review of your design.

This review helps identify areas that may require adjustments to enhance manufacturability.

It's beneficial if you can specify which areas in your design have critical tolerances that must be

met and which can be adjusted slightly if necessary to optimize production time and cost.

Below are some general tolerance guidelines:

General tolerances for CNC machining in metal and plastic

Tolerances for plastic injection molding

Reference charts for CNC machining materials and plastic injection

molding materials

General tolerance for metal 3D printing is +/- 0.5mm

A shrinkage rate of +/- 0.15% is typical for vacuum casting

To ensure precise adherence to your manufacturing and technical

specifications, all requirements

should be clearly detailed in the 2D drawings.