Add to Cart

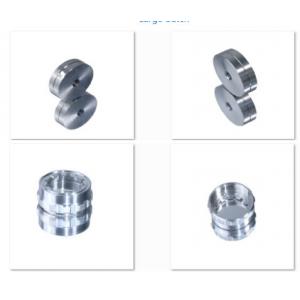

OEM Precision Medical CNC Machining Services Turning Milling Machining Service

Dongguan Jinjie Precision Hardware Co., Ltd. is located in Dongguan City, the world manufacturing center. The factory was established in 2015 with a plant area of 3800 square meters. The company has a professional machining production team. The average core technical personnel have been in the industry for more than 10 years and specialize in processing customized precision parts.

The company has passed ISO9001 and ISO13485 quality system certification, and its customer industries include medical, electronics, aviation, automotive, semiconductor, optics, new energy, precision automation machinery, etc. The company's main equipment is imported CNC, CNC lathes, lathes, milling machines, internal and external cylindrical grinders, hand grinders, slow wire running, medium wire running, fast wire running, spark machines, micro-hole machines, two-dimensional, three-dimensional, height gauges and other advanced equipment processing equipment and testing equipment.

The company uses advanced imported high-precision production equipment, quality control inspection instruments, and reliable testing equipment to provide precision CNC milling and turning, and precision mechanical component processing services to global customers.

Testing equipment display

Stainless Steel | SS201,SS301, SS303, SS304, SS316, SS416 etc. |

Steel | mild steel, Carbon steel,12L14,12L15,4140, 4340,Q235, Q345B, 20#,

45# etc |

Brass | HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 etc. |

Copper | C11000,C12000,C12000 C36000 etc. |

Aluminum | AL6061, AL6063, AL6082, AL7075, AL5052, A380 etc. |

| Process | CNC turning,CNC milling, CNC grinding;CNC lathe machining, CNC boring;CNC drilling, surface treatment |

| Surface treatment | Hardness anodizing black/clear or other colors, steel oxidizing dark-blue, electro-polishing, electroless nickel plating, Chrome plating, silver plating, golden plating etc |

| Tolerance | +/-0.005mm or +/- 0.00019" |

| Certification | ISO9001:2016, ISO13485:2016 |

| Production capacity | depend on complicacy of different products and the quantity |

| Experience | 11 years of CNC machining products |

| Packaging | EPE foam/ Anti-Rust Paper/ Stretch Film/ Plastic bag +Carton or as per customes'requirement |

| Lead time | Sample 5-15 days;Bulk orders are determined according to customer requirements |

| Part size | Diameter from 0.5mm to 1000mm |

| Minimum Order | 1 PCS |

| Maine equipment | Machining center, CNC, Lathe, Milling machine, Drilling machine, Internal and external grinding machine, Cylindrical grinding machine, Tapping drilling machine, Wire cutting machine etc. |

| Testing facility | CMM, projector, roughness tester, hardness tester, concentricity tester. Height tester, . |

Production Capabilities Minimum Tolerance

Outer diameter dimension(turning Process) 0.01mm

Outer diameter dimension(centerless grinding process) 0.005mm

Outer diameter dimension(step grinding process) 0.005mm

Internal diameter dimension(turning process) 0.01mm

Center distance dimension( CNC milling process) 0.01mm

length,width,high(cnc milling process) 0.01mm

surface roughness Ra0.2a

Run-out 0.01mm

Roundness 0.01mm

Flatness 0.01mm

perpendicular 0.01mm

Cylindricity 0.01mm

Our advantages:

1. Precision Cnc stainless steel parts strictly according to customer's drawing,packing and quality request

2. Tolerance: Can be kept in +/-0.005mm

3. The most advanced CMM inspector to ensure the quality

4. Experienced technology engineers and well trained workers

5. Fast and timely delivery. Speedily&professional service

6. Give customer professional suggestion while in the process of customer designing to save costs.

7. Customers can use online payment platform to pay a small amount of sample fee to

shorten the sample production time

8. Quality assurance in accordance with ISO9001:2016 and ISO13485:2016

1. Provide the detailed production schedule for each order.

2. Offering production status with video and photos for each component.

3. Manufacture the parts base on customers' drawings to meet the quality requirements and industry standard.

4. Over 99% orders can meet the lead time requirement.

5. Respond to the enquiry within 24 hours and offer the quotation within 48 hours.

6. Using the first-rank raw materials which also can be traced.

7. Provide the most competitive price with the high quality and service standard.

8. The most reasonable packing scheme for all products.

We can provide precision machining of steel, aluminum alloy, copper alloy, zinc alloy, plastic and castings and other materials, and provide free samples for new and old customers. If the above information is helpful to you, please contact us!

Certification:

Packaging:

1. Jinjie packaging is based on the highest industry standard;

2. Each part is packed independently.

Shipping:

FAQ:

1.How can I get CNC parts sample?

Yes, just need sample cost, we will return it back in mass

production.

We also provide free samples in special conditions.

2:What's the MOQ?

You can make as many pieces as you want. I just need to remind you that there is a world of difference between the price for 1 piece and that for 1000 pieces.

3.How about the lead time?

It depends on quantity, generally 7-20 days after order

confirmation.

4.Can you give me help if my products are very urgent?

Yes, we will try our best to give you help. Because we have our own

factory to produce. We can flexible to adjust our production

schedule.

5.I want to keep our design in secret, can we sign NDA?

Sure, we will not display any customers' design or show to other

people, we can sign NDA.

6. Why should you buy from us not from other suppliers?

High quality, one-stop&professional service for more than 10

years working experience in international trading of machining

industry, fast delivery at 5-15days, small order qty available for

1pcs.

7.Can we know the production process without visiting the factory?

We will offer a detailed production schedule and send pictures and

videos which show the machining progress.

8: How can you guarantee the quality?

We have a powerful QC team to control the quality in every production process.

We believe the best quality is our enterprise life. That’s why we have lots of big group companies.