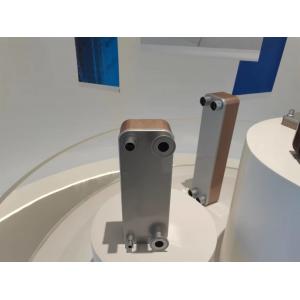

Heat Recovery Systems Copper Plate Heat Exchanger Brazed Energy Efficiency

Add to Cart

Heat Recovery Systems Copper Material Brazed Plate Heat Exchanger

Heat Recovery Systems:

Brazed plate heat exchangers are commonly employed in heat recovery systems, where they extract waste heat from one fluid stream and transfer it to another fluid stream for useful purposes. This helps improve overall energy efficiency and reduce energy consumption.

Early Heat Exchangers: The concept of heat exchange has been around for centuries, but the modern understanding and application of heat exchangers began to emerge in the 19th century. Initially, heat exchangers were constructed using brass or iron materials.

Introduction of Copper: Copper started gaining prominence in heat exchangers due to its superior thermal conductivity compared to other materials. The high thermal conductivity of copper allowed for efficient heat transfer, leading to better heat exchange performance and energy efficiency.

Development of Plate Heat Exchangers: The development of plate heat exchangers revolutionized the industry. The first plate heat exchanger design was patented by Dr. Richard Seligman in 1923. These early plate heat exchangers utilized copper plates with gaskets to form the heat transfer channels.

Copper plate heat exchanger refers to a type of plate heat exchanger that utilizes copper plates as the primary heat transfer surface. Copper is a highly conductive material known for its excellent thermal conductivity, corrosion resistance, and durability. Copper plate heat exchangers are commonly used in various industries and applications where efficient heat transfer and resistance to corrosion are required.

| TYPE | B(mm | C(mm | D(mm) | E(mm) | Thickness (mm) | Weight(Kg) | Max Flow (m3/h) | Design Pressure (Mpa) |

| SB14 | 77 | 42 | 206 | 172 | 9+2.3N | 0.7+0.06N | 8 | 1/3/4.5 |

| SB16 | 78 | 42 | 208 | 172 | 9+2.24N | 0.6+0.049N | 8 | 1/3/4.5 |

| SB18 | 95 | 50 | 210 | 165 | 7+3.1N | 0.7+0.06N | 8 | 1 |

| SB20B | 78 | 42 | 318 | 282 | 9+2.3N | 1+0.08N | 8 | 3/4.5 |

| SB20C | 77 | 42 | 313 | 278 | 10+1.28N | 0.9+0.07N | 8 | 3/4.5 |

| SB26 | 111 | 50 | 310 | 250 | 10+2.32N | 1.3+0.12N | 18 | 3/4.5 |

| SB26F | 107 | 50 | 307 | 250 | 10+1.98N | 1.3+0.1N | 18 | 3/4.5 |

| SB28B | 120 | 72 | 290 | 243 | 10+2.36N | 1.5+0.133N | 18 | 3/4.5 |

| SB28C | 120 | 63 | 290 | 234 | 10+2.36N | 1.5+0.133N | 18 | 3/4.5 |

| SB30 | 126 | 70 | 307 | 250 | 10+2.35N | 2.2+0.16N | 18 | 3/4.5 |

| SB52A | 111 | 50 | 526 | 466 | 9+2.32N | 2.6+0.21N | 18 | 3/4.5 |

| SB52B | 111 | 50 | 526 | 466 | 9+2.32N | 2.6+0.19N | 18 | 3/4.5 |

| SB53 | 106 | 50 | 522 | 466 | 9+2.1N | 2.6+0.27N | 18 | 3/4.5 |

| SB62A | 120 | 63 | 528 | 470 | 10+2.35N | 2.379+0.194N | 18 | 3/4.5 |

| SB62B | 120 | 63 | 528 | 470 | 10+2.35N | 2.379+0.194N | 18 | 3/4.5 |

| SB65 | 125 | 65 | 540 | 480 | 11+2.28N | 2.5+0.228N | 18 | 3/4.5 |

| SB95A | 189 | 92 | 616 | 519 | 11+2.7N | 7.8+0.44N | 42 | 3/4.5 |

| SB95B | 189 | 92 | 616 | 519 | 11+2.7N | 7.8+0.44N | 42 | 3/4.5 |

| SB120A | 246 | 174 | 528 | 456 | 10+2.34N | 7.2+0.52N | 42 | 3/4.5 |

| SB120B | 246 | 174 | 528 | 456 | 10+2.34N | 7.2+0.52N | 42 | 3/4.5 |

| SB190 | 303 | 179 | 695 | 567 | 13+2.3N | 12+0.61N | 100 | 1.6/2.1/3 |

| SB200A | 320 | 188 | 742 | 603 | 14+2.7N | 13+0.67N | 100 | 1.5/2.1/3 |

| SB200B | 320 | 188 | 742 | 603 | 14+2.7N | 13+0.67N | 100 | 1.5/2.1/3 |

| SB200E | 320 | 207 | 742 | 624 | 14+2.7N | 13+0.67N | 100 | 1.5/2.1/3 |

| SB202 | 319 | 188 | 741 | 603 | 16+2.85N | 13+0.957N | 100 | 2.1/3 |

| SB300 | 370 | 118(95.5) | 995 | 861(816) | 17+2.675N | 20+1.26N | 200 | 1.6/2.1/3 |

| SB500 | 304 | 179 | 982 | 854 | 17+2.29N | 26.6+0.93N | 200 | 2.1/3 |

| SB01 | 390 | 204 | 1320 | 1132 | 22+2.75N | 30+1.8N | 300 | 3/4.5 |

Workshop :

Package: